|

|||

|

|

|||

|

Page Title:

Figure 14-9. Input Shaft Installation |

|

||

| ||||||||||

|

|

TM 10-3930-632-34

is firmly seated against the case. Install the clutch pack

the input shaft. Secure the housing to the case using the

(13 and 14) in the case so that the threaded ends of the

screws (46 and 48, fig. 14-5) and lockwashers (47).

shafts enter the bearings; secure with the nuts (1. figs.

Torque bolts to 35 to 45 ft/lbs.

h.

Install the retaining ring (35, fig. 14-2) in the

case (36). Press the bearing cup (34) into the case so

that it is firmly seated against the locating ring (35).

Install the retaining ring (7) and press the bearing (6)

firmly against the ring in the housing (50, fig. 14-5).

I.

Press the bearing (31) into the housing until it

rests firmly against its integral retaining ring. Install the

input shaft (14) in the bearing, and secure with the

locating ring (30). Make sure the two oil seals (28) are

installed on the shaft as shown in figure 14-9. Install the

stator (27, fig. 14-5), using shims (29) to take up play of

the shaft (41). Secure the stator with capscrews (26)

and lockwire.

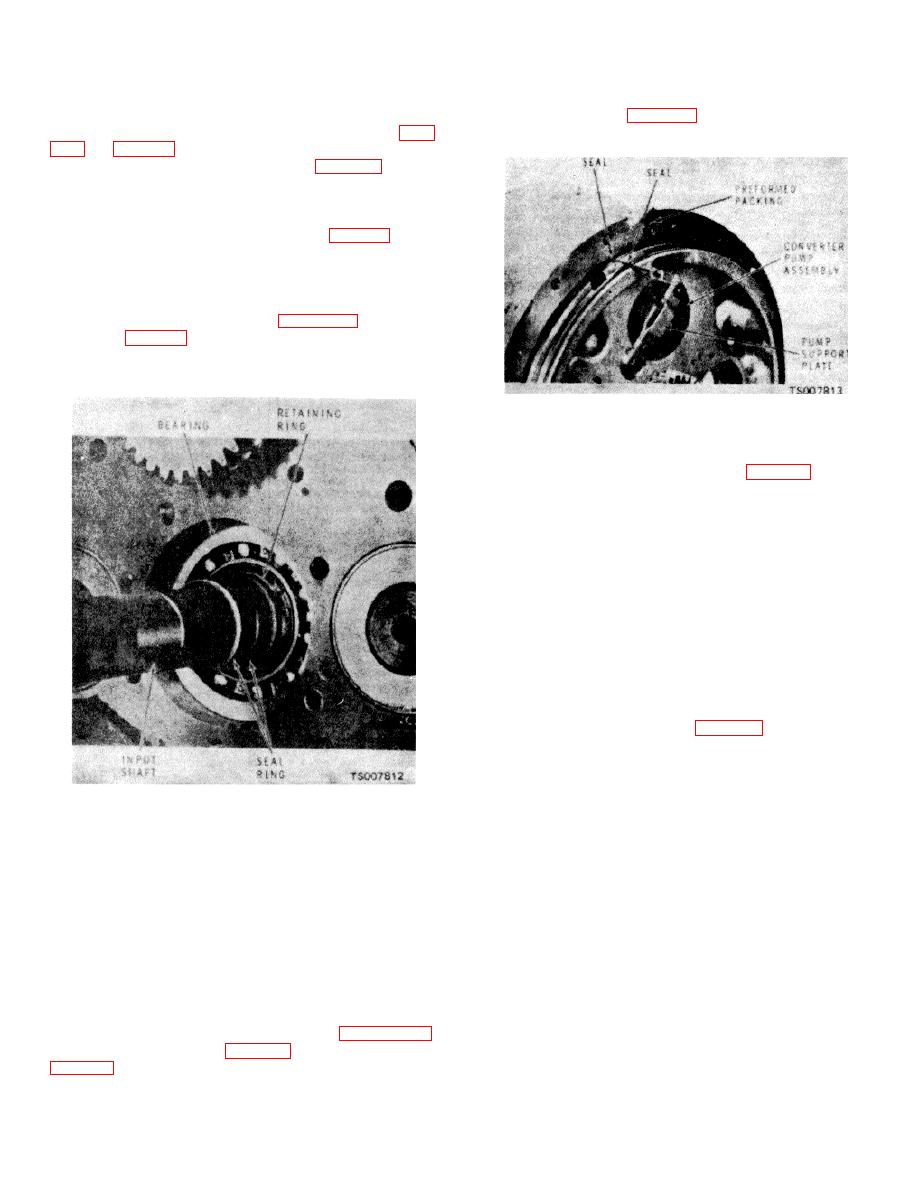

Figure 14-10. Torque Converter Housing

Showing Pump and Seals

m.

Position the rear bearing (34, fig. 14-2) on the

pinion shaft and insert the pinion shaft part way into the

housing (36). Install the spacer (12), gear (11), and

spacer (9) on the pinion drive shaft. Seat the shaft and

install the front bearing (6), preformed packing (5), and

brake drum (3); secure with the nut (2) torqued to 150 to

200 ft/lbs. When the nut is tightened, check the rotation

of the pinion shaft. If the shaft binds, add washer (10). If

the shaft has any end play, remove washer (10). When

the proper washer thickness is obtained, the shaft shall

have a preload of 8 to 10 inch-pounds. Add shims to

decrease preload, subtract to increase preload. After

proper adjustment, install the seal (4) in the housing and

reinstall the brake drum (3) and nut (2). Secure the nut

to 150 to 200 ft/lbs and lock with the cotter pin (1).

n.

Position the gear (25, fig. 14-5) on the stator

so that the teeth of the gear mesh with those of the

converter pump drive gear (34).

o.

Insert the ball (11), spring (10) and seal (9)

into the cover plate (6); secure in place with the plug (8).

Figure 14-9. Input Shaft Installation

Insert the stop (20), regulator piston (19), pin (22), and

spring (18) into the body (21); position the washer (17)

j.

Position the gear (34) on the drive shaft of the

on the plug (16) and turn the plug into the body.

converter oil pump (35) and press the gear over the

p.

Position the washer (23) and seals (24) on the

shaft. Place the washer (33) on the shaft and secure in

body; turn the body into the cover.

place using the retaining ring (32).

q.

Position seal (2) and preformed packings (13

k.

Position the converter pump assembly on the

and 14) in the cover. Coat both sides of gasket (12) with

plate (40) and secure them together using the screws

gasket sealer and place the gasket (12) on the

(36) and lockwashers (38). Torque bolts to 20 to 25

ft/lbs. Insert the pump into the housing and secure the

plate in position using the screw (37) and lockwasher

(39).

I.

Position new seals (42 and 43) and preformed

packing (44) on the housing as shown in figure 14-10.

Position the housing (50, fig. 14-5) on the housing (36,

14-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |