|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-12

WARNING

(3) Hold a light in a position to light the

timing hole on the flywheel housing. Crank the engine

Dry cleaning solvent P-D-680 is toxic and

until the dead center mark on the flywheel lines up with

flammable. Wear protective goggles and

the pointer in the timing hole.

gloves and use only in a well ventilated

(4) Remove the distributor cap, rotor, and

area. Avoid contact with skin, eyes, and

dust cover. With the timing hole pointer on the flywheel

clothes and don't breath vapors. Do not use

dead center mark, the contact points in the distributor

near open flame or excessive heat. The

should just start to open to fire the No. 1 cylinder.

flash point is 100F - 138F. (38C -

(5) If the contact points are not just

59C). If you become dizzy while using

beginning to open, loosen the distributor clamp arm (fig.

cleaning solvent, get fresh air immediately

and get medical aid. If contact with eyes is

made, wash your eyes with water and get

medical aid immediately.

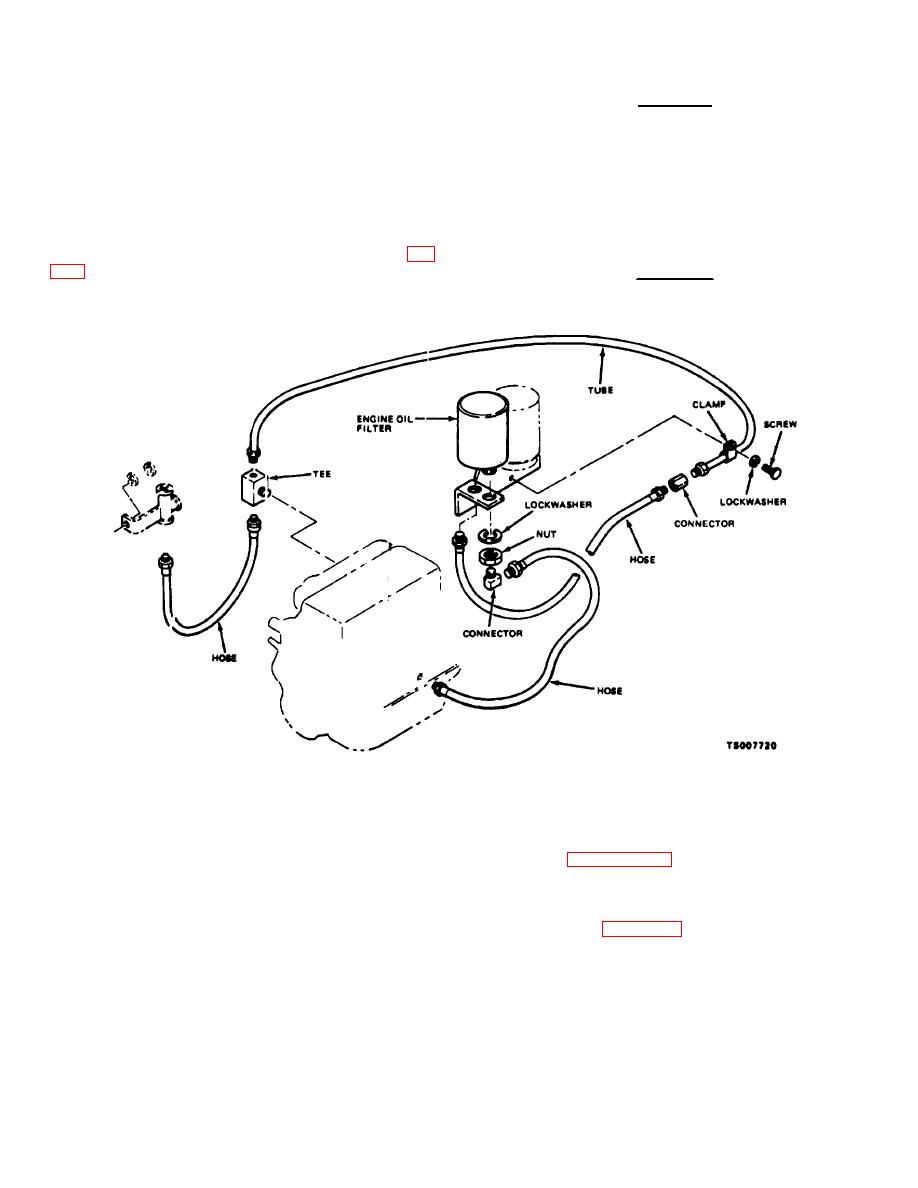

Figure 4-47. Engine Oil Filter, Removal and Installation

4-67. Engine Oil Filter

(6) To determine exactly when the points

a. Service. Service the engine oil filter as

open or close, connect a test light between the

distributor primary terminal and ground. The light will be

described in paragraph 4-8. Filter service shall coincide

off when the points are closed and will go on when the

with engine oil change.

b. Removal.

points open.

(7) Replace the timing hole cover and the

(1) Remove the oil filter and associated

distributor dust cover, rotor, and spark plug.

parts as shown in figure 4-47.

(2) Flush the hoses with a cleaning solvent

Paragraphs 4-65 and 4-66 deleted.

which will not attack rubber. Clean all remaining parts

with dry cleaning solvent P-D-680.

Figures 4-45 and 4-46 deleted.

Change 2 4-61

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |