|

|||

|

|

|||

|

Page Title:

Check piston ring gap as follows: |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

TA067461

TA067459

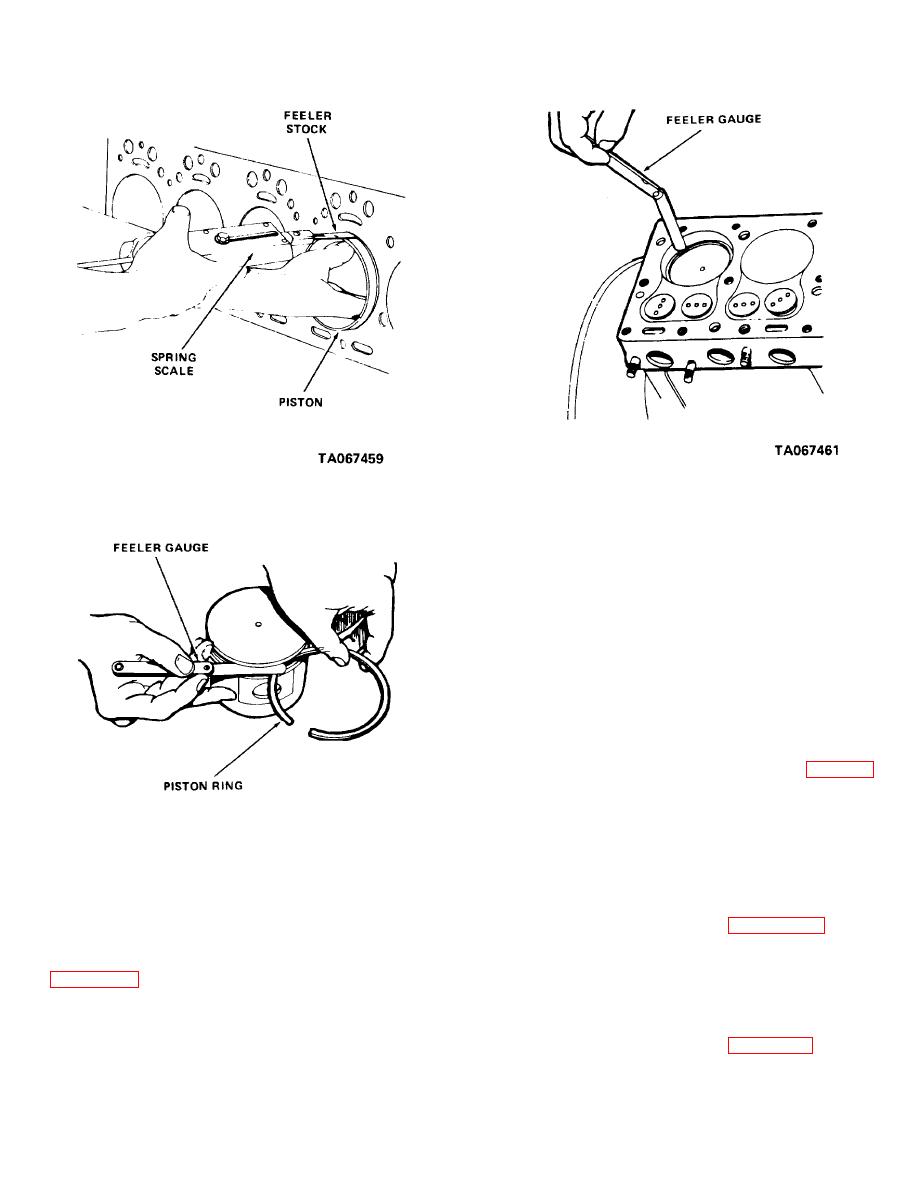

Figure 11-21. Checking piston ring gap.

Figure 11-19. Checking piston fit in bore.

Diameter must be 0.8593 to 0.8591 inch (21.86 to 21.82

mm).

(2) Measure length of piston pin. Length must

be 2.691 to 2.676 inches (68.3 to 67.9 mm).

(3) Measure inside diameter of piston pin hole

in bearing. Diameter must be 0.8597 to 0.8595 inch

(21.836 to 21.831 mm). Maximum wear limits diameter

is 0.8607 inch (21.86 mm).

(4) Check fit of piston pin in piston. Pin must

slide in with a light push at room temperature.

(5) Check piston pin fit in bearing. Clearance

must be 0.0006 to 0.0002 inch (0.015 to 0.0005 mm).

Desired fit is 0.0004 inch (0.010 mm).

19.

(1) Check bearing shells with a micrometer.

Thickness must be 0.0616 to 0.0613 inch (1.56 to 1.55

TA067460

mm). Minimum thickness wear limit is 0.608 inch (1.54

Figure 11-20. Checking ring-to-land clearance.

mm).

(2) Check piston pin bearing hole diameter.

(5)

Check piston ring gap as follows:

Diameter must be 0.914 to 0.913 inch (23.21 to 23.19

(a) Insert piston in cylinder bore in an

mm).

inverted position, and install each ring, one at a time,

(3) Press bearing (5, fig.

11-18) into

about two inches (50.8 mm) into bore. Bring bottom

connecting rod (6).

edge of the piston groove up against the ring to square it

(4) Install bearing shells (10) and bearing cap

up and measure gap with a feeler gage as shown in

(9) on connecting rod. Secure with bolts (8) and nuts

(7). Tighten bolts to a torque of 40 to 45 foot pounds

(b) Top piston ring and second and third

(54:2 to 67.7 N ).

m

ring gap must be 0.008 to 0.018 inch (0.202 to 0.457

(5) Install piston pin (3) in bearing. Place

mm).

assembled connecting rod in fixture (fig. 11-22). Check

(c) Fourth ring gap must be 0.015 to

rod for twisted or bent condition. Piston pin hole must

0.055 inch (0.038 to 1.39 mm).

be parallel to and in the same plane with large bore in

g. Check piston pin as follows:

bearing end.

(1) Measure outside diameter of piston pin.

11-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |