|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-34

in the pressure side of the steering circuit.

system to fill. Check for pressure of air leaks in the

system. After running for one minute, shut engine off

b. Operate pump at full engine speed, and

turn the steer wheels to their limit. The opening pressure

and recheck oil level. If low, fill to proper level. Refer to

LO 10-3930-630-12 for proper grade oil.

must be set at 1100 psi (77.3 kg/cm2). Adjust the pump

relief valve setscrew in or out to set opening pressure.

(3) Refer to paragraph 3-21 and set the

main hydraulic relief pressure (in control valve) to 1900

to 2000 psi (133.5 to 140.6 kg/cm2)

NOTE

Always start the hydraulic pump

3-26.

Hydraulic Pump, Relief Valve Adjustment

under no load conditions to prolong

a. Install a pressure gage (2000 psi) (140.6

pump life.

kg/cm2)

Section VII. MAST AND CARRIAGE

3-27. Description

3-28.

Hydraulic Carriage, Removal and

The mast and carriage support, and lift the load. Both

Disassembly

are of welded construction. Studs to mount the bearings

a. Removal. Refer to TM 10-3930-630-12 and

are welded to the mast and carriage.

remove the carriage.

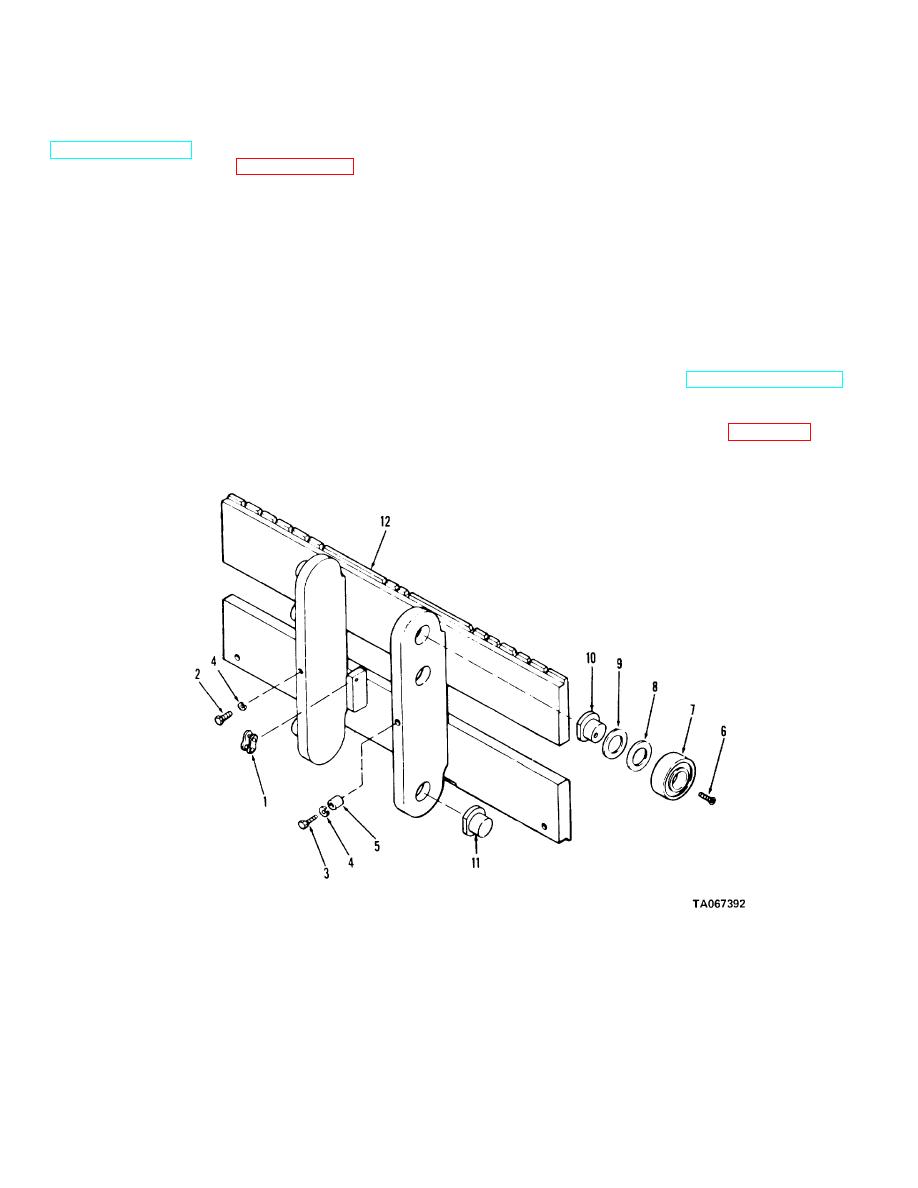

b. Disassembly. Disassemble the carriage in

numerical sequence as illustrated on figure 3-10.

1 Chain link

7 Bearing

2 Screw

8 Shim

3 Screw

9 Shim

4 Cock washer

10 Stud

5 Spacer

11 Stud

6 Screw

12 Carriage frame

Figure 3-10. Hydraulic carriage, disassembly and reassembly.

3-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |