|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

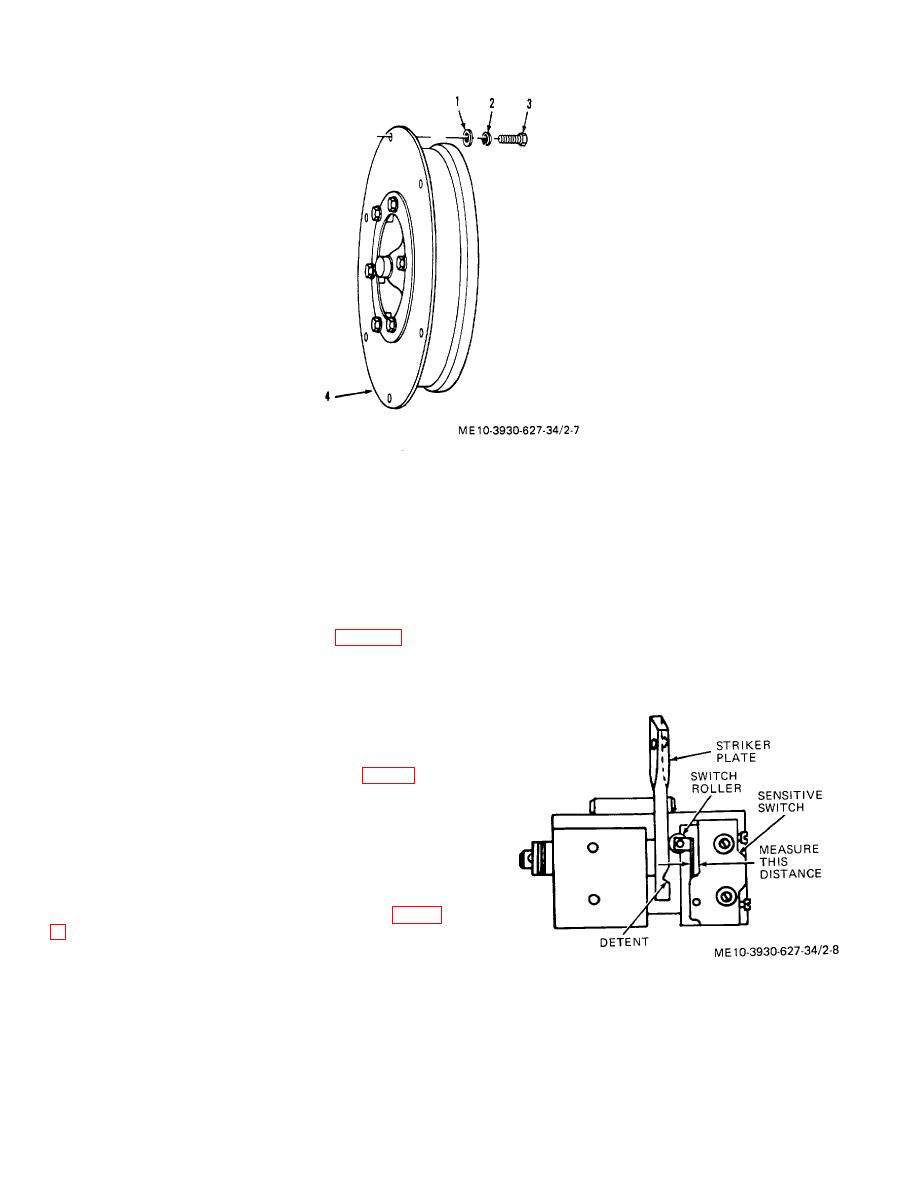

1.

Flat washer

2.

Lock washer

3.

Screw

4.

Torque converter

Figure 2-7. Torque converter

(b) At this point mea ure the distance

s

b. Installation.

between the switch body and roller arm with a feeler

(1) Install the torque converter on the engine

gage.

flywheel, with timing marks on drive plate next to hole in

(c) Subtract 3/32 inch from feeler gage

flywheel marked on removal. (see note, para 2-7).

(2) Reverse the removal procedure (a. above).

reading, repeat ( ) above, and tighten switch in this

b

Be careful to keep the clutch spline shaft aligned with

position.

the splines in the hub of the torque converter during

installation, to prevent binding.

(3) After completing installation, and linkages are

connected, adjust inching controls as follows:

(a) Attach pressure gage (0-250 psi range) to

forward clutch pressure port (for location see fig. 7-4).

(b) Adjust the adjusting screw in the inching

valve in or out as required to obtain maximum forward

clutch pressure with the brake pedal in the fully released

position (foot off brake).

(c) Disconnect pressure gage, install pipe

plug in pressure port, and tighten adjusting screw lock

nut.

(4) Adjust neutral safety switch as follows (fig. 2-

(a) With the switch roller just contacting the

flat area of the striker plate which actuates it, adjust the

switch position until the switch clicks.

Figure 2-8. Neutral safety switch adjustment.

2-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |