|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

slack when the spring is attached to the brake crank

(2) Remove pin and cotter pin, loosen the

assembly. Adjust the linkage after installation.

jam nut, and rotate lower yoke (8 fig. 4-3) to adjust brake

shoe position.

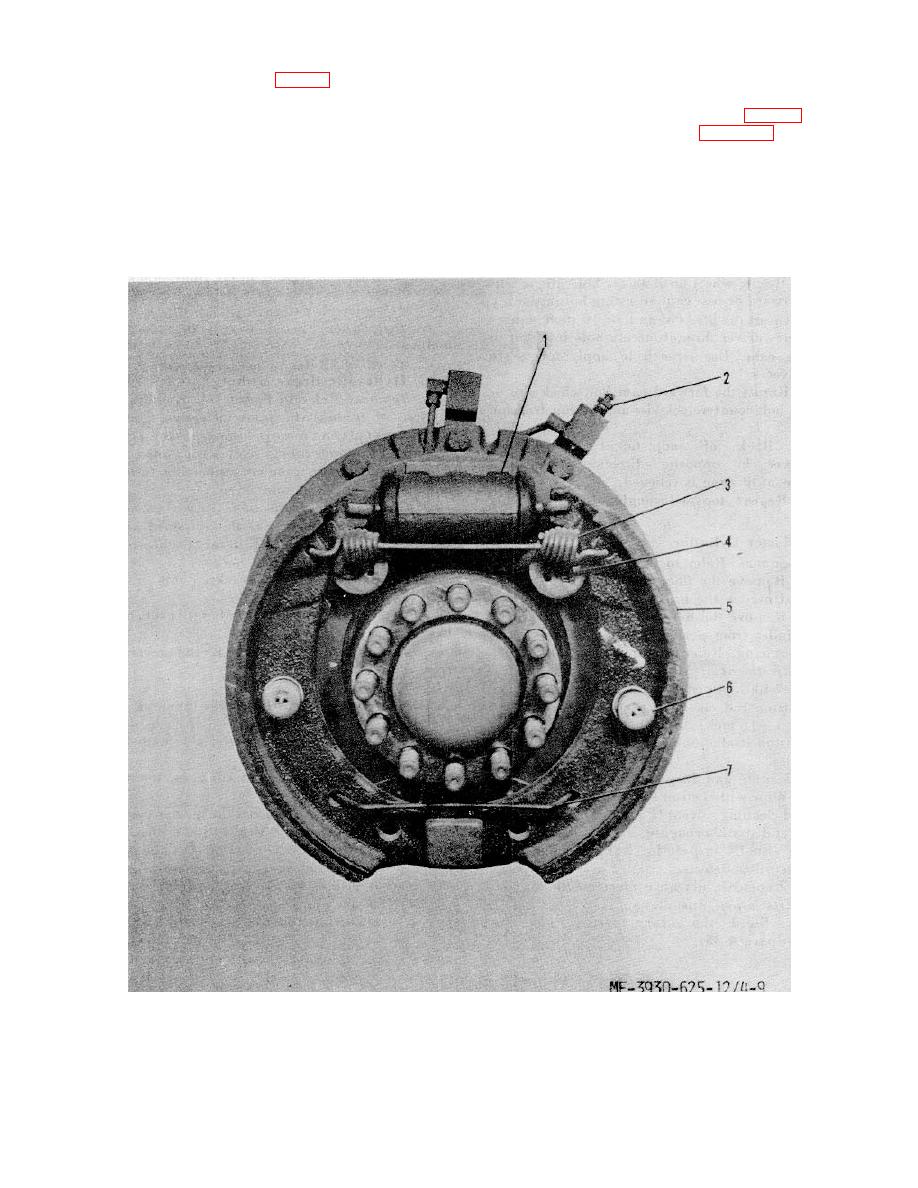

4-31. Service Brakes

c. Cleaning and Inspection.

a. Removal of Shoe Assembly (fig. 4-9).

(If Clean with an approved cleaning solvent (Federal

(1) Remove wheel (para 4-37).

Specification P-D-680) and dry thoroughly.

(2) Remove return spring.

(2) Inspect for worn cable, breaks, cracks,

(3)

Remove retainers, springs and

or other defects.

washers.

(3) Replace defective parts as necessary.

(4) Remove brake shoes.

d. Installation. Installation is the reverse of

(5). Remove retainer spring.

removal. With seat down and directional control switch

in either forward or reverse, there should be very little

2. Bleed valve

4.

Cam adjusting bolt

6. Retaining spring and

1. Wheel cylinder

3. Shoe return spring

assembly

washers

5. Brake shoe

7. Retainer spring

Figure 4-9. Service brakes.

4-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |