|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(5) Install the radiator grille (TM 10-3930-

624-12).

(6) Check the oil reservoir to be sure the oil

level is correct. Run the pump for one minute with

no load to allow the system to fill. Check the inlet

and outlet ports for leaks. Tighten the connections

to eliminate any leaks. If the pump is cavitating,

tighten the inlet line at the pump. After one minute

of running, shut down the engine and recheck the

oil level in the reservoir. If it is low, fill to the proper

level. If severe foaming is noted, check for a leak in

the inlet line or for improper oil. Refer to the

current LO 10-3930-624-12 for the proper oil.

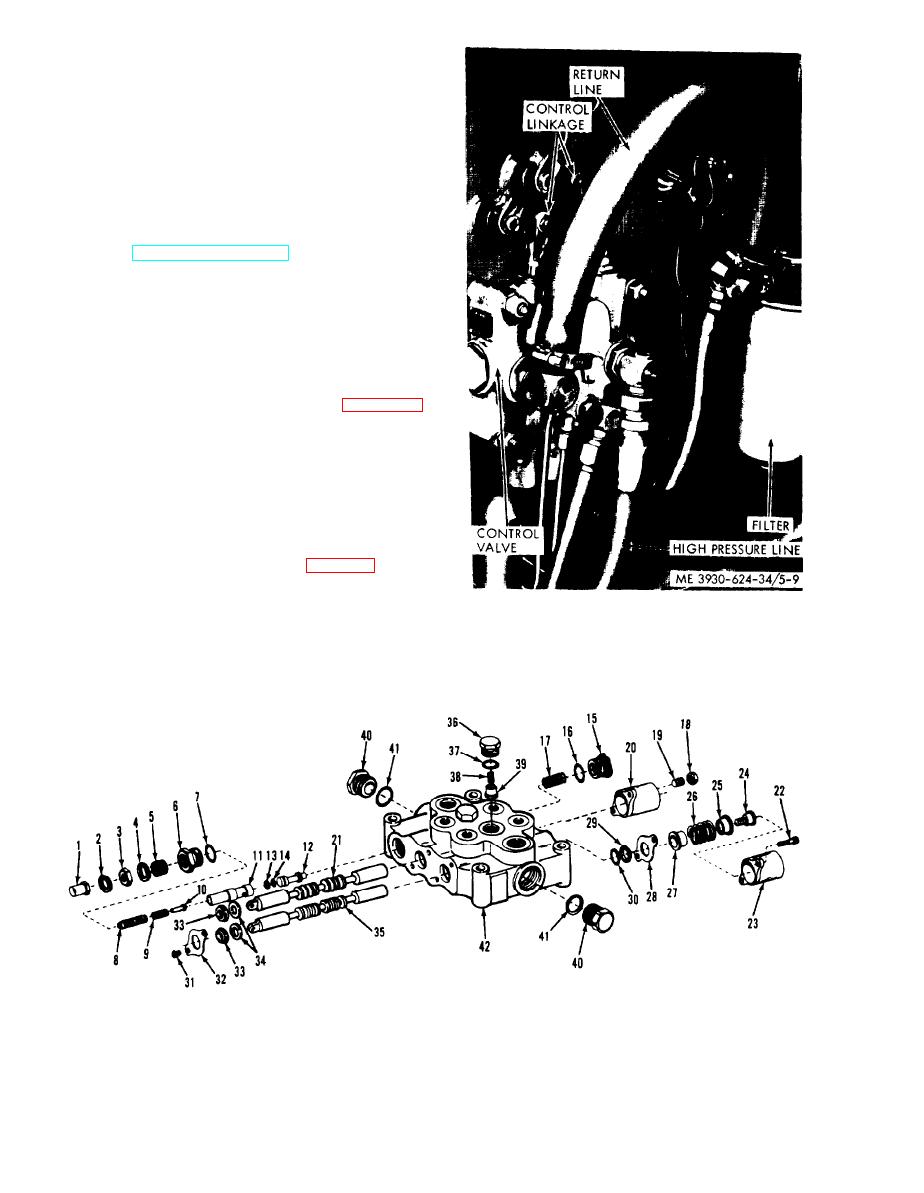

5-6. Control Valve

a. Removal.

Note. Before removing the valve make sure that the lift

cylinders are collapsed. Tilt the mast backward and forward to

relieve the pressure in the control valve.

(1) Disconnect the control linkages at the

valve spool connections as shown in figure 5-9.

(2) Tag and disconnect all hydraulic lines to

the control valve. Cap or plug openings.

(3) Remove the mounting hardware and the

control valve.

b. Disassembly.

(1) Clean the exterior of the control valve and

dry with compressed air. Clamp the valve in a vise.

Be careful not to damage the housing.

(2) Remove the cap nut (1, fig. 5-10), washer

(2). locknut (3). washer (4), plug (5) and plug (6).

Remove the preformed packing (7) from the plug.

Figure 5-9. Control valve.

ME 3930-624-34/5-10

Figure 5-10. Control valve, exploded view.

5-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |