|

|||

|

|

|||

|

Page Title:

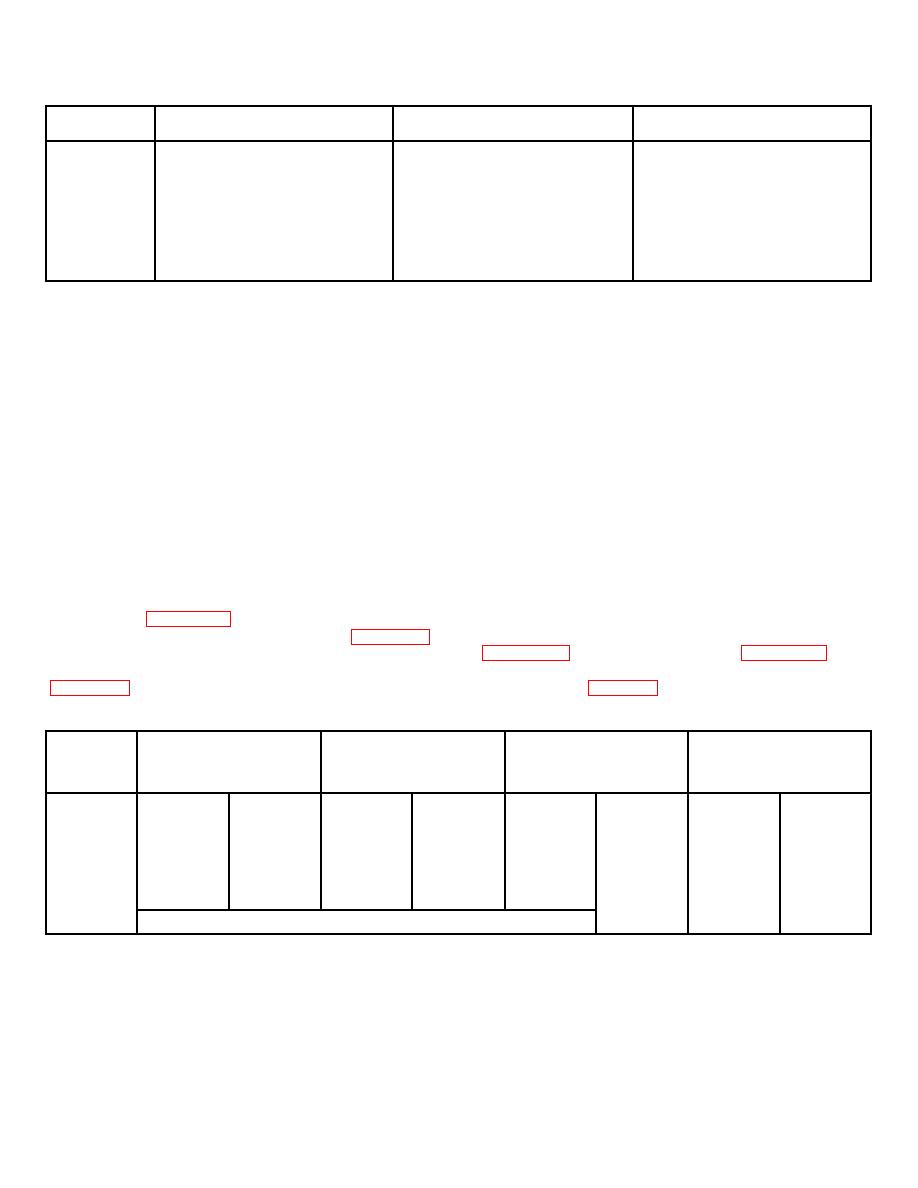

Figure 7-9. Table of Engine Dynamometer Run-In Procedures |

|

||

| ||||||||||

|

|

TM 10-3930-623-34

Manifold Vacuum In

Step

Time

Inches of Mercury

RPM

1

Warm-up period 10 minutes

No load

600 to 800

2

10 minutes

15 inches

1500

3

15 minutes

10 inches

2000

4

15 minutes

10 inches

Governed speed

5

30 minutes

6 inches

Governed speed

6

10 minutes

Open throttle (full load)

Governed speed

Figure 7-9. Table of Engine Dynamometer Run-In Procedures

1. Road test transmission for satisfactory operation

NOTE

in forward and reverse operation, and for unusual

noises.

If more than one gage is available, all

pressure points may be tested at one

2. With brakes applied, and transmission engaged,

time.

first in forward, then in reverse, check stall speed, or

maximum speed at which engine will operate loaded by

7-87. INCHING VALVE ADJUSTMENT. The inching

the torque converter. With oil temperature at 200 deg F,

control valve spool is limited to a travel of 0.50 inches.

engine speed should be between 1615 rpm and 1785

rpm.

Higher stall speed indicates slippage in the

During this travel, controlled by the brake pedal, the

transmission clutches, defective control valve, linkage

master cylinder push rod must be free to insure

maladjustments, or low fluid level in the transmission.

complete release of the brakes. Adjust as follows:

Lower stall speed indicates engine lacks normal power,

and must be repaired before results of this test are valid.

1. Check brake pedal to insure pedal arm will be

parallel to the underside of the floor plate with 1/8 inch

3. If stall speed is high, test pressures for values

clearance. Adjust pedal stop bolt as required.

indicated in figure 7-9.

Points at which pressure

measurements are made are shown in figure 1-7.

2. Adjust inching control valve piston (23,

Remove plug in passage to be tested, install pressure

gage, and operate engine at speed specified in

spool is fully in when screw is against the brake pedal

inching rod (16, figure 7-8).

Converter

Engine

Main Line

Charging

Forward Clutch

Reverse Clutch

RPM

Pressure (PSI)

Pressure (PSI)

Pressure (PSI)

Pressure (PSI)

Min

Max

Min

Max

Min

Max

Min

Max

500

20

30

15

25

15

25

15

25

1000

58

68

42

50

50

58

50

58

1500

110

120

74

84

77

87

77

87

2000

120

135

84

101

80

93

80

93

With inching valve fully actuated

200

0

0

Figure 7-10. Table of Transmission Test Pressures

7-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |