|

|||

|

|

|||

|

Page Title:

STARTING MOTOR ARMATURE INSPECTION AND TEST |

|

||

| ||||||||||

|

|

TM 10-3930-623-34

2. Check all lead wires for fraying, broken strands,

4. Check armat ure assembly for open coils and

or corrosion. Discard defective lead wires.

shorts and grounds using conventional test light and

growler tests.

3. Discard broken or bent springs and brush

holders. Measure spring tension with a spring gage.

CAUTION

Discard springs if pressure of brushes to cummutator is

less than 35 ounces, or if springs are discolored or

Do not touch test lamp probes to

distorted.

shaft bearing surfaces. Arcing will

damage smooth surfaces.

4. Examine commutator end bell for cracks,

distortion, or excessive side plan. Discard if damaged or

7-27.

STARTING

MOTOR

worn.

INSPECTION.

7-26. STARTING MOTOR ARMATURE INSPECTION

1. Check starting switch terminals and terminal

AND TEST.

nuts for stripped or crossed threads. Discard parts,

which cannot be repaired.

1. Check bearing surface at ends of shaft for pitting

and scoring. Examine shaft for straightness. Discard

2. Use a conventional test light and a 12 volt

armature (34, figure 4-21) if pits or scratches cannot be

battery to check circuit continuity of switch and relay. If

repaired with a fine grade hone, or if shaft is bent.

the test lamp does not light when switch is closed,

2. Examine commutator for roughness, high mica,

discard switch.

and burning. If commutator is dirty or discolored, clean

with 00 sandpaper. Check commutator with a dial

indicator for out-of-round. If out-of-round exceeds 0.003

7-28.

STARTING

MOTOR

DRIVE

ASSEMBLY

inch, turn down commutator on lathe, and undercut mica

INSPECTION.

1/16 inch between segments.

1. Examine drive pinion and shaft assembly for

3. Examine all windings for properly soldered

worn or broken teeth. Check movement by rotating drive

connections.

pinion. Discard defective or damaged assembly.

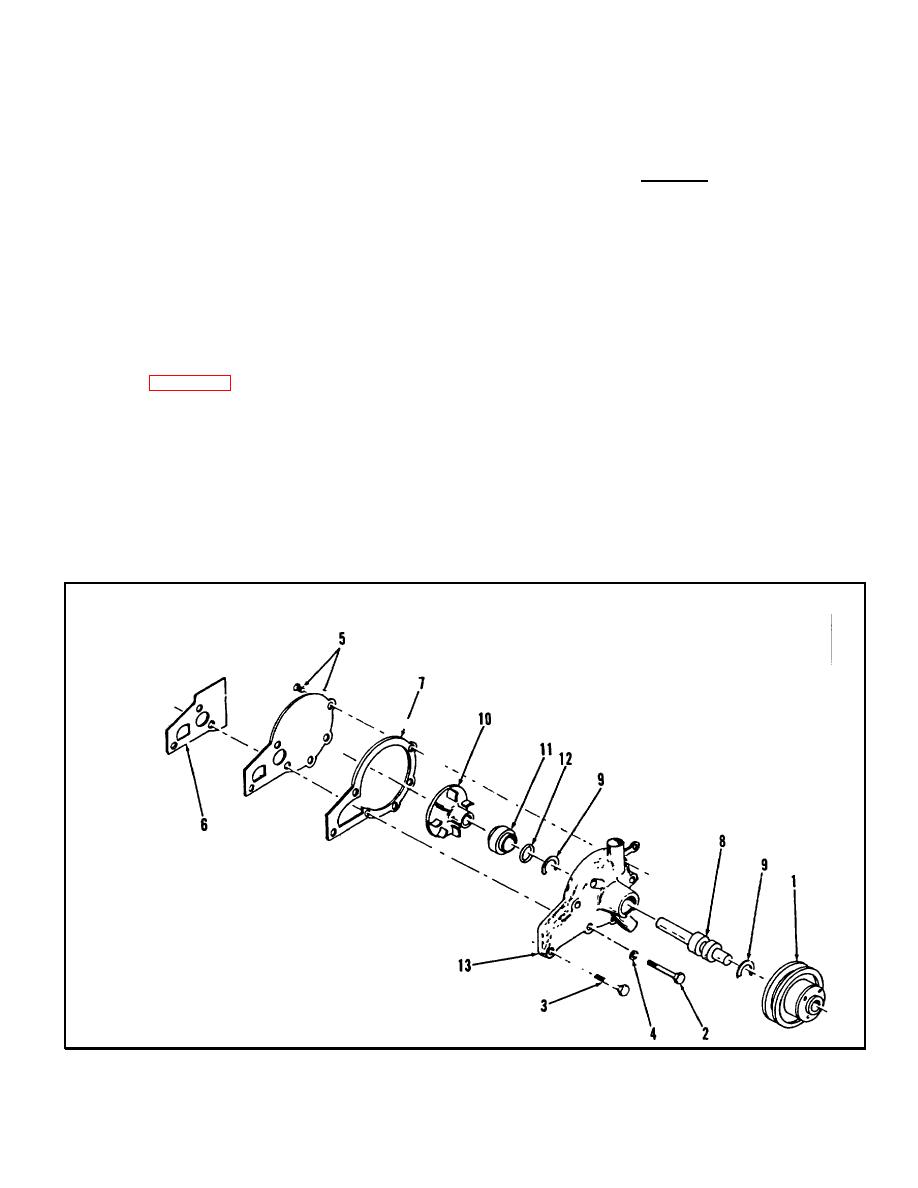

1.

Drive Pulley

2.

Screw

3.

Screw

4.

Washer

5.

Rear Cover

6.

Gasket

7.

Body Gasket

8.

Bearing and Shaft

9.

Retaining Ring

10.

Pump Impeller

11.

Pump Seal

12.

Gasket

13.

Pump Body

Figure 7-4. Engine Water Pump, Exploded View

7-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |