|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-34

1-6. The fork lift trucks are powered by a Continental

FS-244 Military Standard engine.

1-7. DETAILED DESCRIPTION.

The Continental FS-244 Military Standard engine is

rated at 82.3 horsepower when operating at 2800

revolutions per minute.

1-9. The full pressure lubrication system includes a

gear-type oil pump with adjustable bypass valve to

maintain suitable pressure through all speeds, and a

replaceable element oil filter.

1-10. The fuel system includes a mechanical diaphragm

fuel pump, driven by the engine camshaft, a single

venturi updraft carburetor, and a mechanical governor

which limits the maximum speed of the engine by closing

the carburetor throttle valve when the engine reaches

the governed speed. The carburetor air cleaner uses a

disposable paper filter element.

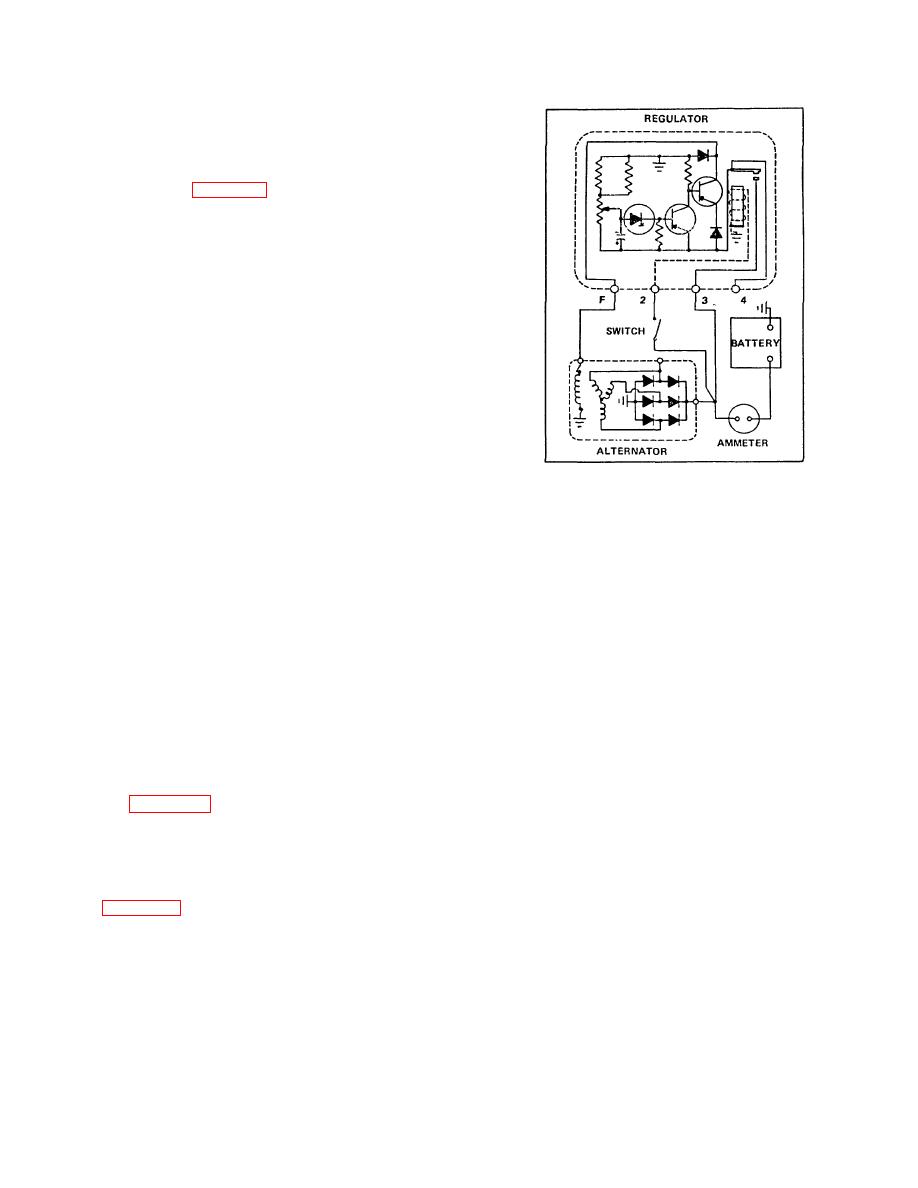

Figure 1-3. Charging System Basic Schematic

designed and constructed to give long service with a

minimum of maintenance. The rotor is mounted on a

ball bearing at the drive end, and a roller bearing at the

The flow of current to the field circuit of the alternator

slip ring end, and each bearing has a grease supply

provides the magnetic field for the alternator. When the

which eliminates the need for periodic lubrication. Two

engine is started, the alternator builds up voltage. This

brushes are used to carry current through the two slip

causes current to flow to charge the battery and/or

rings to the field coil which is mounted on the rotor. The

power accessories.

brushes are extra long and under normal operating

conditions will provide long periods of service. The

2. As alternator speed increases or the accessory load

stator windings are assembled on the inside of a

decreases, alternator voltage builds up to a

laminated core that forms part of the frame. Six rectifier

diodes, mounted in the slip ring end frame, are

predetermined value at which the regulator is set or

connected to the stator windings. The six diodes change

adjusted. The electrical control portion of the regulator

the ac voltage to dc voltage which appears at the BAT

then places a higher voltage on the base of the transistor

terminal on the alternator. A capacitor, or condenser,

than is impressed upon the emitter, and the transistor is

mounted in the end frame protects the diodes from high

turned "off". With no current flow in the emitter-collector

voltages. Current output of the alternator is self4-limiting

circuit, there is no current flow in the field coil of the

by design to its rated maximum, regardless of speed or

alternator. As a result, alternator voltage drops below

external circuit conditions.

An externally mounted

the setting or adjustment of the regulator.

voltage regulator limits the operating voltage to a

specified value through the full speed range of the

3. Then the electrical control portion of the regulator

alternator. Figure 1-3 shows a schematic view of the

alternator and regulator.

places a lower voltage on the base of the transistor than

that on the emitter, and the transistor is again turned

1-12. VOLTAGE REGULATOR. The transistor is an

"on". With current flow again in the emitter-collector and

electrical device made of semiconductor materials which

field coil circuit, the magnetic field is reestablished in the

is used as a switch to control the alternator field current

-alternator, and alternator voltage can again build up to

in order that alternator voltage can be limited to a proper

the setting of the regulator.

value. Figure 1-3 is a greatly simplified diagram of the

alternator and regulator circuit. A brief description of the

4. Thus, the switching "on" and "off' of the transistor

operation follows:

regulates the amount of field current supplied to the

alternator. The frequency of this switching is dependent

1. When the ignition switch is closed, battery voltage

primarily upon the accessory load and alternator speed.

supplies current through the emitter (E) and collector (C)

Under certain conditions the "on" and "off' cycle is

of the transistor to the field coil of the alternator. This

repeated-as much as 7,000 times per second.

emitter-collector circuit is complete since the transistor is

turned "on" by a higher voltage on the emitter than on

the base (B), which permits emitter-base current to flow.

1-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |