|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

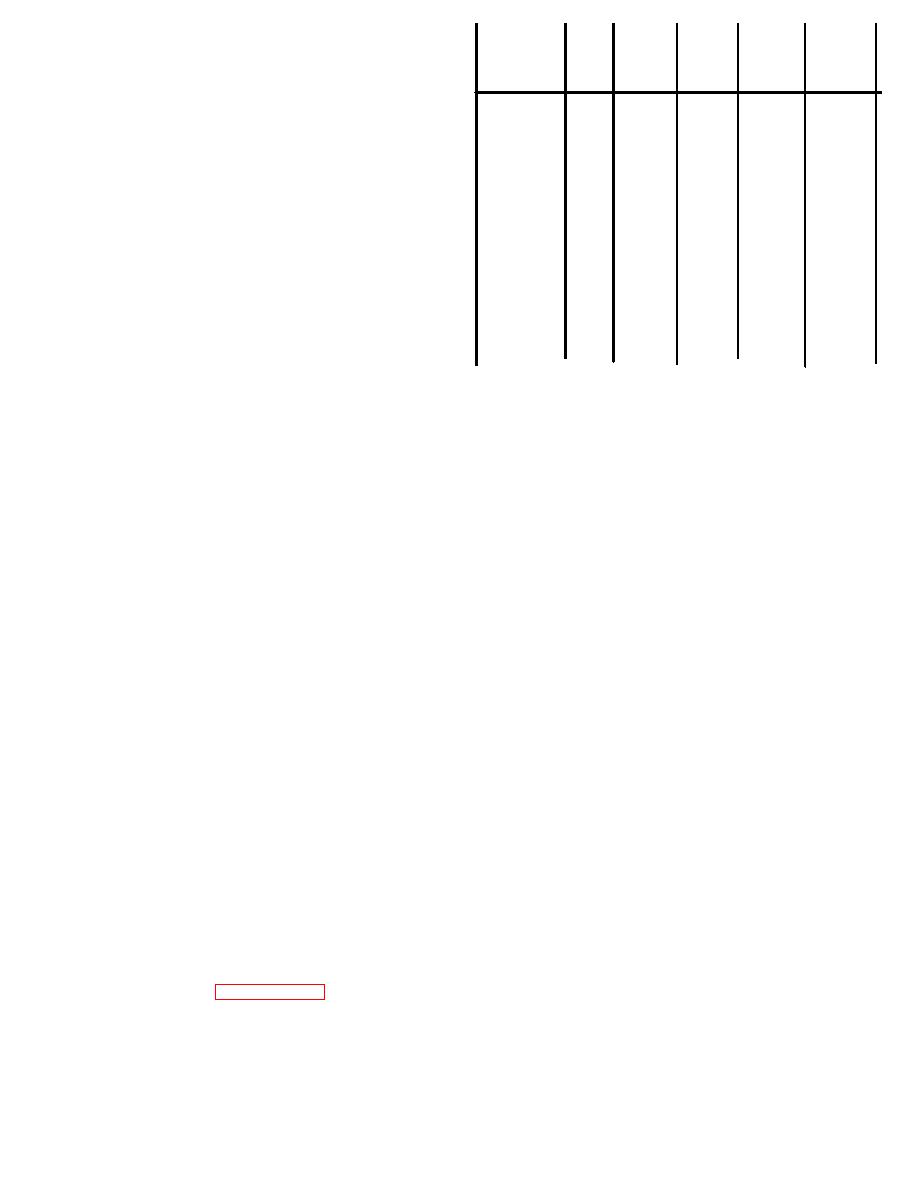

Maintenance

After

Semi-

Check levers for proper operation.

Reference

Use

Daily

Weekly

Quarterly Annual

5-27. LIFT CHAINS.

----

----

X

----

----

----

Inspect for worn or broken links.

----

----

----

X

----

----

Lubricate complete chain.

Lube Chart

----

-----

----

----

----

Check for secure mounting.

----

----

-----

X

----

---

5-28. UPRIGHT ASSEMBLY.

Check for secure mounting on drive axle

----

----

----

----

X

----

assembly.

----

----

X

----

----

----

Inspect for free operation with no binding

during tilt and hoist operations.

----

----

X

----

----

----

Check for proper latching operation (where

Lube Chart

----

----

----

----

----

applicable).

Lubricate carriage and crosshead rollers.

pressure indication after the engine has operated for 30

seconds, stop the engine and determine the cause.

5-29. BEFORE OPERATION SERVICE.

b. When the engine is started, the ammeter will

5-30. The before operation service detailed below must

normally indicate a high charging rate and then gradually

be performed before attempting to start the engine prior

return to a slight charging rate. If a discharge indication

to operating the fork lift truck.

or absence of indication is noted, stop the engine and

investigate the cause.

a. Fill the fuel tank with the proper grade of fuel.

c. The normal coolant temperature range for

b. Check and fill the radiator with the proper

engine operation should be between 165 to 190

coolant.

degrees Fahrenheit. If the temperature gauge indicates

temperature outside these limits, stop the engine and

c. Check level of lubrication oil in crankcase. Add

investigate the cause.

proper weight and grade oil as necessary.

5-33. ENGINE. Check engine at various speeds for

5-31. ROAD TEST PROCEDURES.

evidence of overheating, lubricant leakage and other

abnormal conditions. Note any excessive noise or

5-32. Road tests on the fork lift truck should be

vibration of the engine over its entire speed range.

conducted

following

maintenance

and

service

operations. Periodic road tests should also be scheduled

5-34. TRANSMISSION. Place the fork lift truck in

if the vehicle is subjected to infrequent use. The road

motion and check forward action of transmission. Check

test should provide sufficient operational time to insure

reverse drive operation. The transmission shift lever

proper operation of the vehicle. When the engine is

should slide smoothly into position without a tendency to

started observe the indicating instruments as described

slip out of gear. Note any excessive vibration of shift

in the subsequent steps. Before attempting to drive the

lever when decelerating or accelerating the vehicle.

vehicle, but while the engine is operating, check the

operation of the brakes, steering wheel, truck lighting

system and hydraulic system in accordance with their

5-35. SERVICE AND HAND BRAKES. Test .operation

respective operating instructions. Observe the following

of service brakes at start of road test while traveling at

instruments during the road test to determine proper

various vehicle speeds. Brake action should be positive

operation.

a. The oil pressure gauge should normally indicate

pressure as explained in paragraph 4-27d. If there is no

oil

29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |