|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-611-35

CHAPTER 3

REPAIR INSTRUCTIONS

Section I. ELECTRICAL SYSTEM

3-1. General

core. If a grounded armature coil is evidenced, replace

the armature.

This section provides information useful in the

f.

Reassembly.

Refer to figure 3-3 and

repair of the forklift electrical system. The electrical

reassemble the hydraulic pump motor.

system consists of a drive motor, hydraulic pump motor,

g. Pump Coupling Chain Reassembly and

wiring, and various other components which assure the

proper operation of the truck.

chain.

3-2. Hydraulic Pump Motor

the hydraulic pump and the hydraulic pump motor as an

assembly.

the hydraulic pump and the hydraulic pump motor as an

assembly.

b. Pump Coupling Chain Removal and

coupling chain.

c. Disassembly.

Refer to figure 3-3 and

disassemble the hydraulic pump motor.

d. Cleaning, Inspection and Repair.

(1) Wipe all electrical parts with a clean,

dry cloth. Clean all other parts with dry cleaning solvent

(Federal Specification P-D-680) and dry thoroughly.

(2) Inspect all wires and terminals for

breaks and corrosion. Inspect brushes for amount of

wear and evidence of chipping. Inspect brush holders

for proper spring tension (2.5 lbs.). Inspect commutator

for burns and high mica. Inspect chain and sprocket,

and other parts for breaks, cracks, dents, loose or

missing mounting hardware, or other defects.

(3) Clean corrosion from wires and

electrical connections, tighten or replace loose or

missing hardware. Replace a damaged or worn chain or

sprocket. If necessary, undercut commutator mica to a

depth equal to the thickness of the mica and take a light

cut from the commutator in a lathe. If brushes are

shorter than 13/16 inch, replace and sand in as

necessary. Replace damaged parts.

the probes to each end of the field coil terminals to test

for continuity. Test for grounded field coils by touching

one probe to the field coil circuit and the other to the

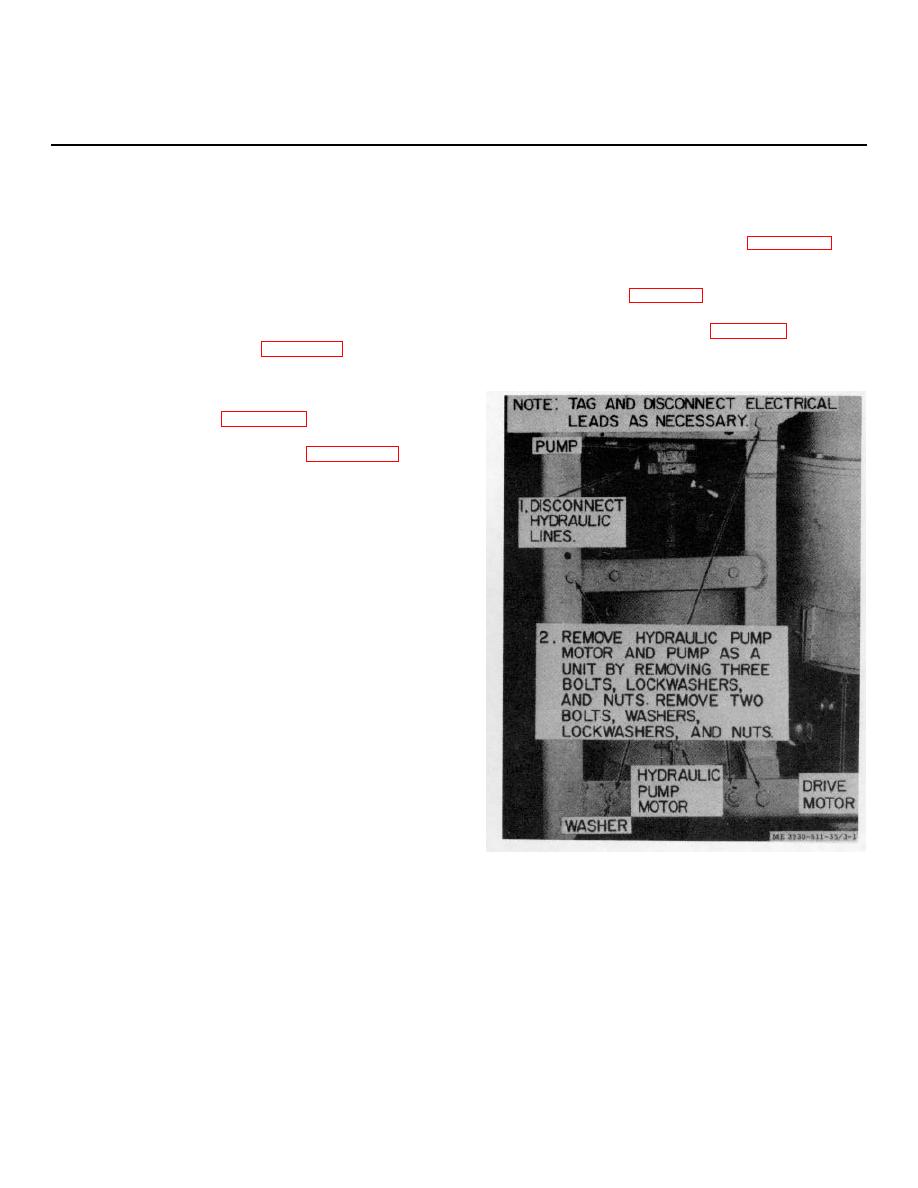

Figure 3-1. Hydraulic pump and hydraulic pump motor,

field core frame. If lack of circuit continuity or grounded

removal and installation.

coil is indicated, replace the field coils. Touch one test

probe to the commutator and the other to the armature

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |