|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

HYDRAULIC

6. Slide cover over gear shafts, being careful not

4. Secure pump and adapter to the timing gear

to damage O-rings, and make sure that the seal ring is

case. Observe the alignment between mounting bore,

in position when flange makes contact with pump body.

adapter and pump frequently to avoid binding of

Secure mounting flange to body.

components. Tighten each mounting bolt alternately

and torque evenly.

7. Insert relief valve ball into body, tap lightly with

a brass drift and light hammer to insure seating. Install

5. Replace hydraulic hoses and tighten sufficiently

spring and cap.

to eliminate pressure and vacuum leaks.

F. INSTALLATION

6. Be sure no load is imposed on the hydraulic

system, then prime the pump. When pump is primed

1. Flood pump with oil to remove any foreign

and the system is charged, check the pressure relief

particles and insure lubrication.

setting, adjust if necessary.

G. BREAK-IN PROCEDURE

2. Place new gasket and O-ring on the adapter.

Place adapter in its mounting bore on the engine. Be

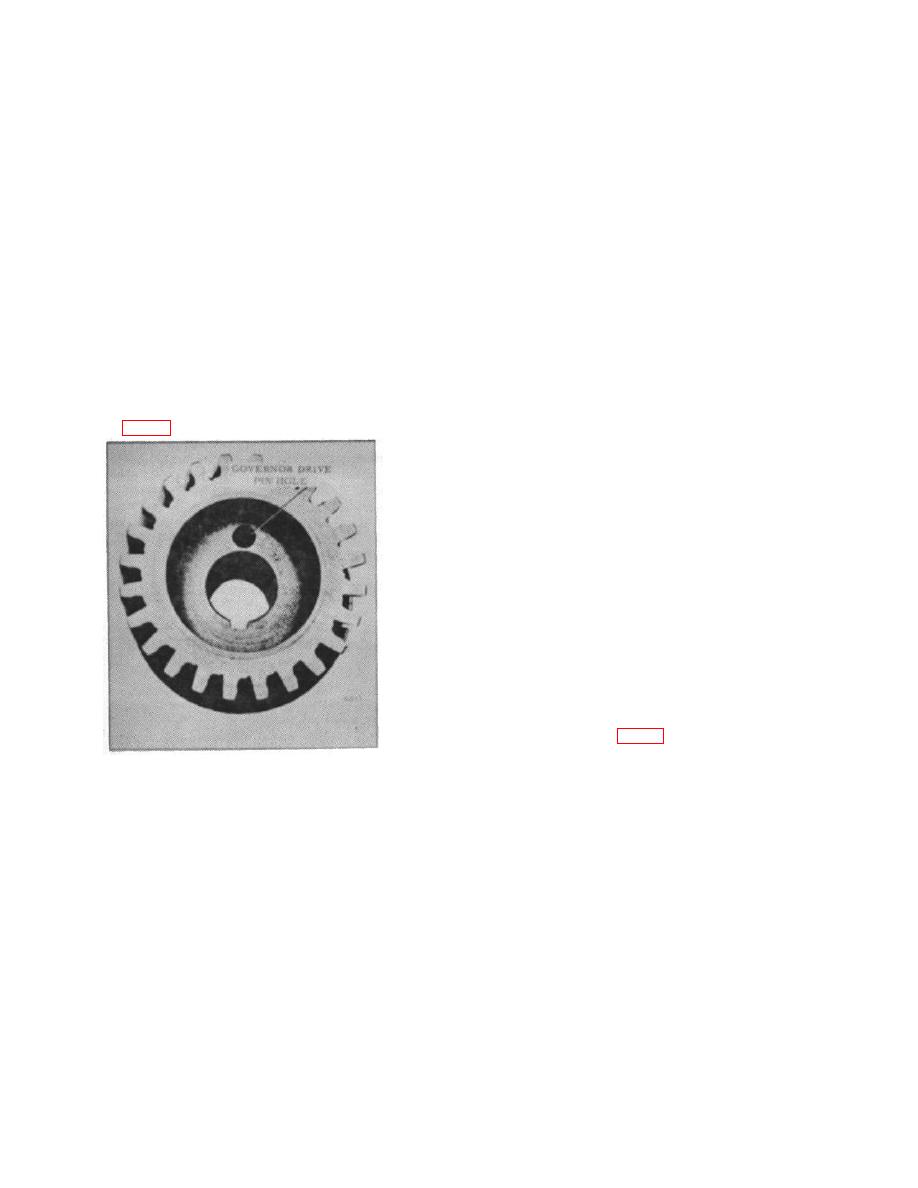

sure the governor drive pin is in the pump gear governor

1. Break-in will be required for new pumps, rebuilt

pin hold. (Fig. 6)

pumps, or those out of service for an extended time.

2. Prime pump: Fill suction hose with correct

hydraulic oil. Pour oil in suction and discharge pump

ports before securing hoses. Due to position and/or

location, complete filling of suction hose may be

impossible, so fill to permissible limit.

3. Start engine and run at 1000 RPM until pump

picks up prime. Prime pick-up may be checked by

activating control lever. Run engine at 1000 RPM for 10

minutes after prime pick-up.

MANUAL CONTROL VALVE

A. GENERAL

The Control Valve (Fig. 7) consists of a one piece body,

operating spools, two check valves for each spool, an

Figure 6.

adjustable relief valve and the necessary seals and

plugs.

3. Place a new gasket on pump and work pump

into a position near the adapter. Align pump drive key

The body is constructed of a one piece casting, cored to

with the keyway in the adapter gear bore. Push pump

contain passages for a full series parallel circuit. Cored

shaft into the adapter bore being careful not to lose the

body outlet ports are machined for removable SAE O-

drive key.

ring fittings.

B-148

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |