|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

BRAKES

B. BLEEDING - COMPLETE SYSTEM

3. Partially fill a clean glass container with clean

brake fluid. Place the free end of the bleeder hose

below the surface of the fluid in the container.

1. Make sure the entire working area around the

master cylinder is clean, then remove the filler cap.

Inspect brake fluid for discoloration, foreign particles,

4. If the pressure bleeder has been attached:

viscous fluid, and sludge. If unnatural conditions exist,

the system must be flushed. If foreign particles are

First open the pressure valve on the bleeder and then

found, the entire system must be checked. Using the

the bleed valve on the wheel cylinder. Permit fluid to

"process of elimination" method, start at the master

flow from the system until it flows clean and free of air

cylinder and work toward the wheel cylinder farthest

bubbles. Close the bleed valve on the wheel cylinder

from the master cylinder. Open the first connection and

and remove bleeder hose.

check the fluid that drains from it. If the particles are

still present, repeat the process on the next connection.

5. If pressure bleeder is not available:

Repeat checking until the wheel cylinders are reached,

If particles are still present, both wheel cylinders should

After making sure the master cylinder is full, open the

be inspected, and repaired as necessary.

wheel cylinder bleed valve; operate the brake pedal,

allowing it to move slowly from one extreme to the other

2. Check brake fluid level and air pressure in the

until the fluid worked from the system is clean and free

pressure bleeder; then attach bleeder to the master

of air bubbles. Watch the fluid level in the master

cylinder. (Do not open the valve on the bleeder at this

cylinder and keep sufficient fluid in the reservoir to

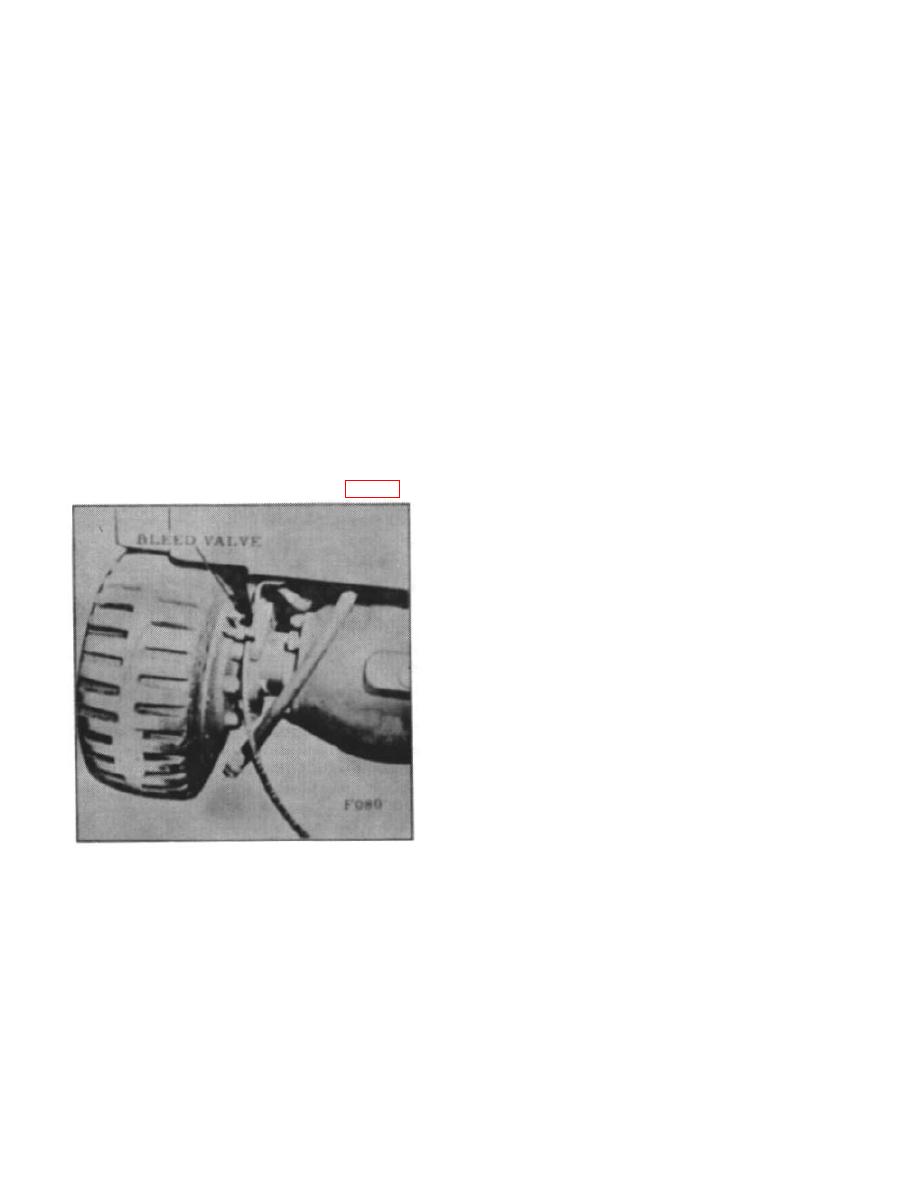

time.) Affix bleeder hose to the bleed valve on the wheel

eliminate the possibility of air being pumped into the

cylinder farthest from the master cylinder. (Fig. 15)

system.

6. Check the pressure in the pressure bleeder or

fluid level in the master cylinder if bleeder is not being

used. Clean the glass container and repeat the bleeding

process on the other wheel.

NOTE: In order to detect any foreign materials that may

be in the cylinder being bled, the glass container must

be clean at the beginning of the bleeding process.

C. PARTIAL BLEEDING

1. To bleed an individual wheel, follow the

procedure given for bleeding the complete system, but

bleed air from only the cylinder being serviced.

2. To bleed the master cylinder, connect pressure

bleeder to the master cylinder, then open pressure valve

and loosen the hydraulic

Figure 15.

B-137

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |