|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ELECTRICAL

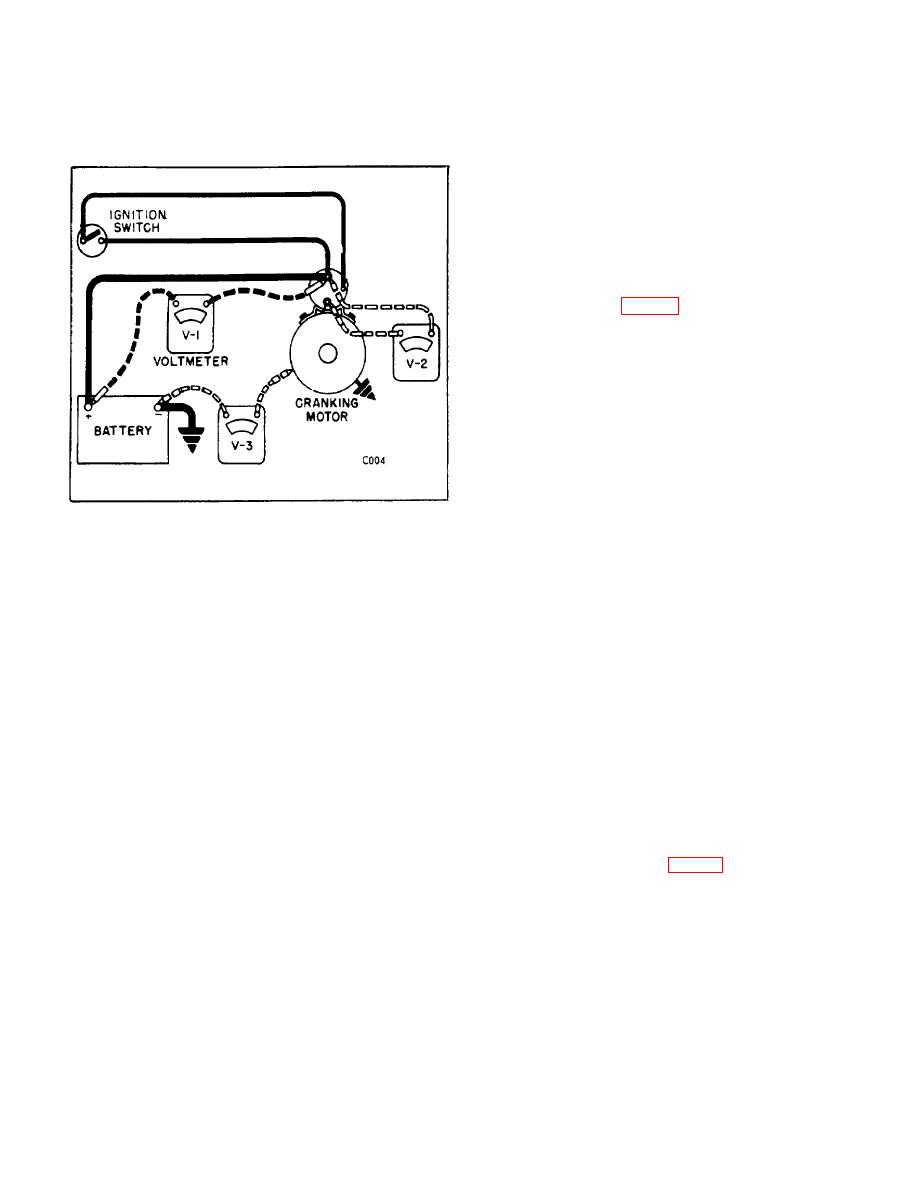

and V-3 (with voltmeter connected to the negative (-)

D. REMOVAL

battery post and the starter field frame).

1. Disconnect: the battery ground cable from the

battery; the cable from the cranking motor, solenoid or

magnetic switch; the wires from the solenoid or

magnetic switch.

2. Remove the two capscrews holding the motor to

the flywheel housing. Lift the motor toward the rear of

the truck.

E. DISASSEMBLY (Fig. 31)

NOTE: Normally, the cranking motor

should be dismantled only to the

point where repair or replacement of

parts can be made. However, the

cranking

motor

should

be

disassembled completely at regular

intervals for the cleaning and

inspection of all parts.

1. Remove screw and lock washer attaching field

Figure 32.

coil connector strap to lower terminal on solenoid.

2. If V-1, V-2, or V-3 exceeds 0.5 volt, excessive

2. Remove through-bolts attaching commutator end

resistance is indicated in that part of the circuit being

frame and field frame to drive end housing. Remove

checked. Locate and eliminate the cause for any

commutator end frame.

excessive voltage drop in these circuits in order to

obtain maximum efficiency from the starting system.

3. Remove field frame from armature and drive-

housing.

3. If starter fails to crank engine, first make sure

battery is not discharged, then check solenoid operation.

4. Remove armature and drive assembly from drive

If solenoid plunger fails to pull in, the trouble may be

housing, tilting armature as necessary to disengage lugs

due to excessive resistance in the solenoid control

on shift lever from drive collar.

circuit. Check all wiring and connections from ignition

switch to solenoid for loose or corroded connections.

5. Remove two screws and lock washers attaching

solenoid to drive housing. Remove solenoid and return

4. If cause of excessive resistance is not apparent,

spring from drive housing and plunger.

connect a short jumper lead across the solenoid

"battery" and "S" terminals. If solenoid plunger pulls in,

6. Remove over-running clutch drive assembly

trouble is in solenoid control circuit. Check for defective

from armature shaft as follows:

ignition switch. If solenoid plunger does not pull in with

jumper lead connected, solenoid is defective and must

a. Slide thrust collar (Fig. 33) off end of armature

be replaced.

shaft.

B-75

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |