|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ELECTRICAL

(1) A shorted battery cell.

Starter pinion is shifted into mesh with wheel ring gear

teeth and starter circuit is completed by the solenoid

(2) A high voltage regulator setting.

when the solenoid is energized by the key starting-

ignition switch, Primary circuit to ignition coil is also fed

1. Shorted Battery Cell: Checks for shorted battery

from the solenoid while the starter is operating.

cells should be made as this can cause the battery to be

overcharged.

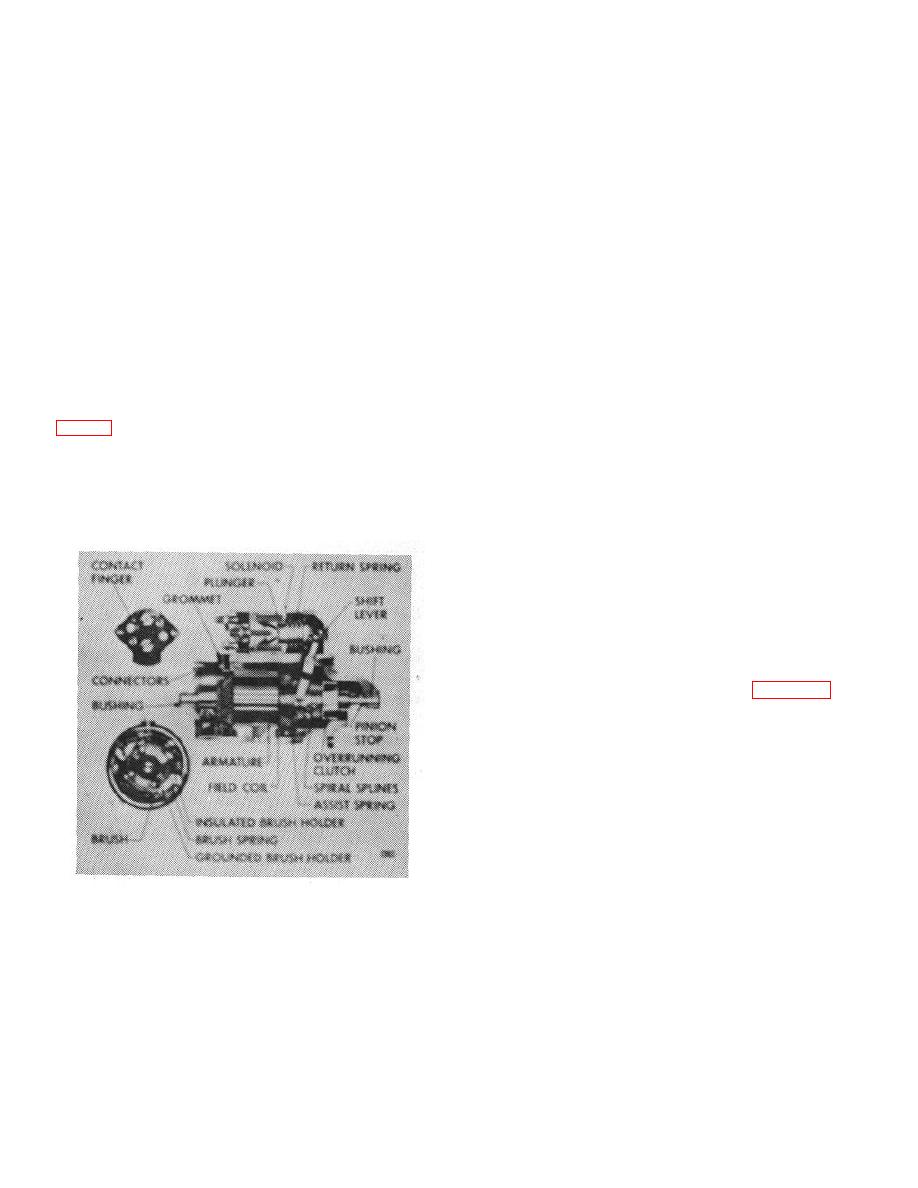

The drive end housing is extended to enclose the entire

shift lever mechanism and solenoid plunger. The

2. High Voltage Regulator Setting: If no circuit

solenoid flange is mounted on the drive end housing,

defects are found, yet the battery remains overcharged,

with sealing compound used between flange and field

the cause is probably a high voltage regulator setting.

frame. The shift lever return spring is a compression

type spring located inside the solenoid case. A special

assist spring is located around the armature and the

CRANKING MOTOR

collar of the clutch drive. This assist spring aids the

solenoid in overcoming the return spring force in the first

A. GENERAL

movement of the clutch along the armature shaft.

The 12 volt cranking motor is a 4 pole, 4 field coil unit

B. PERIODIC MAINTENANCE

that has the solenoid, solenoid plunger, and solenoid

shift lever mechanism enclosed in the drive housing.

No periodic lubrication of the cranking motor solenoid is

required. The cranking motor and brushes can be

drive is used to engage the cranking motor pinion with

inspected only when the unit is disassembled, so no

the flywheel. The armature shaft and clutch have

service is necessary between overhaul periods.

mating spiral spines that prevent transfer of full cranking

power until the pinion is fully engaged with the flywheel

C. STARTING CIRCUIT TESTS

ring gear.

NOTE: The following tests are for

solenoid

equipment

cranking

motors. However, they can be used

as guides to check the starting

circuits

of

cranking

motors

controlled by magnetic switches.

1. Disconnect the primary lead to the distributor to

prevent engine starting. Referring to Figure 32, and

with starter cranking engine during each check, measure

V-1 (with voltmeter connected to the positive (+) battery

post and the solenoid battery terminal), V-2 (with

voltmeter connected to the solenoid battery terminal and

solenoid motor terminal),

Figure 31.

B-74

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |