|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ELECTRICAL

8. Install the springs and brushes into the brush

holder, and insert a straight wire or pin into the holes at

the bottom of the holder to retain the brushes. (Fig. 10)

Then attach the brush holder assembly onto the end

frame, noting carefully the proper stack-up of parts as

shown in Figure 10. Allow the straight wire to protrude

through the hole in the end frame.

9. Assemble the heat sink onto the slip ring end

frame. (Fig. 15)

Figure 16.

H. INSPECTION

The frequency of inspection is determined largely by the

type of operating conditions. High speed operation, high

temperatures, and dust and dirt all increase the wear of

brushes, slip rings and bearings.

Figure 15.

At regular intervals, inspect the terminals for corrosion

10. Remove the tape over the slip ring end frame

and lose connections, and the wiring for frayed

bearing and slip ring end of the rotor shaft. Make sure

insulation. Chock the mounting bolts for tightness, and

the shaft is clean.

the belt for alignment, proper tension and wear. When

tightening belt tension, apply pressure against the stator

11. Slide the slip ring end frame over the rotor

laminations between the end frames, and not against

shaft. Align the scribe marks previously made. Secure

either end frame.

the assembly with the through bolts, tightening them

alternately and evenly.

I. INSTALLATION

12. Withdraw the wires or pins holding the brushes

1. Position alternator at mounting bracket and

of the slip rings. Check the output of the alternator.

install mounting bolts, nuts, and lock washers.

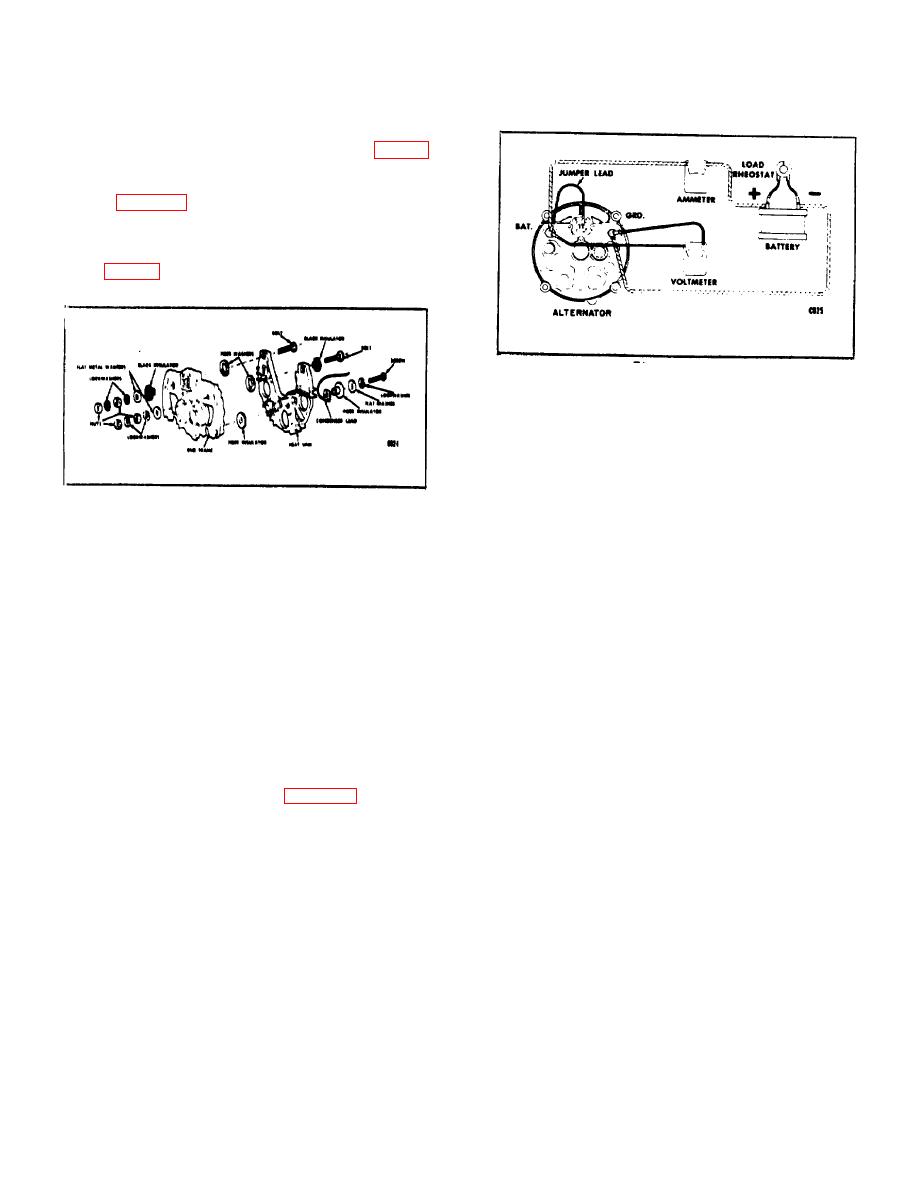

G. OUTPUT CHECK

2. Place belt in alternator pulley, then attach

adjusting arm to alternator drive end frame with cap

1. Check the alternator on a test bench, make

screw and washers. Adjust belt tension then tighten

electrical connections as shown in Figure 16, operate at

adjusting arm cap screw and mounting bolts.

specified speed, and check for rated output.

3.

Connect wires to generator according to

2. Adjust the load rheostat, if necessary, to obtain

identification made at time of removal, or by referring

the desired output.

to the wiring diagram. Make sure connections are tight,

NOTE: Connect the negative battery

post to the alternator frame.

B-64

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |