|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ENGINE

are "in", that is, in the bottom of the driver slots, the

space between the top of the conical shaped race

bushing and hair pin clip should be .230" - .240". Use

.010" spacer washers to obtain required space. The

governor shaft is pressed into the gear and secured with

a screw that is partially in the shaft and partially in the

gear.

ASSEMBLY

1. When reassembling pistons and connecting

rods, use a good ring compressor and oil the bores

thoroughly. A hammer handle may be used to tap the

pistons out of the ring compressor into the cylinder bore.

2. Use care to prevent damage to cylinder bore

finish by the connecting rods when the connecting rods

are assembled over the crank pin.

Locate them

carefully to prevent damage to the bearing surface, and

crankshaft journals.

3. Always lubricate the bearings with clean engine

oil when assembling. Tighten the bearings to specified

torque. Use lockwires as required to prevent loosening

of nuts and screws.

4. Clean the cylinder head and block surfaces

thoroughly before installing the gasket.

Tighten all cylinder head capscrews evenly and in

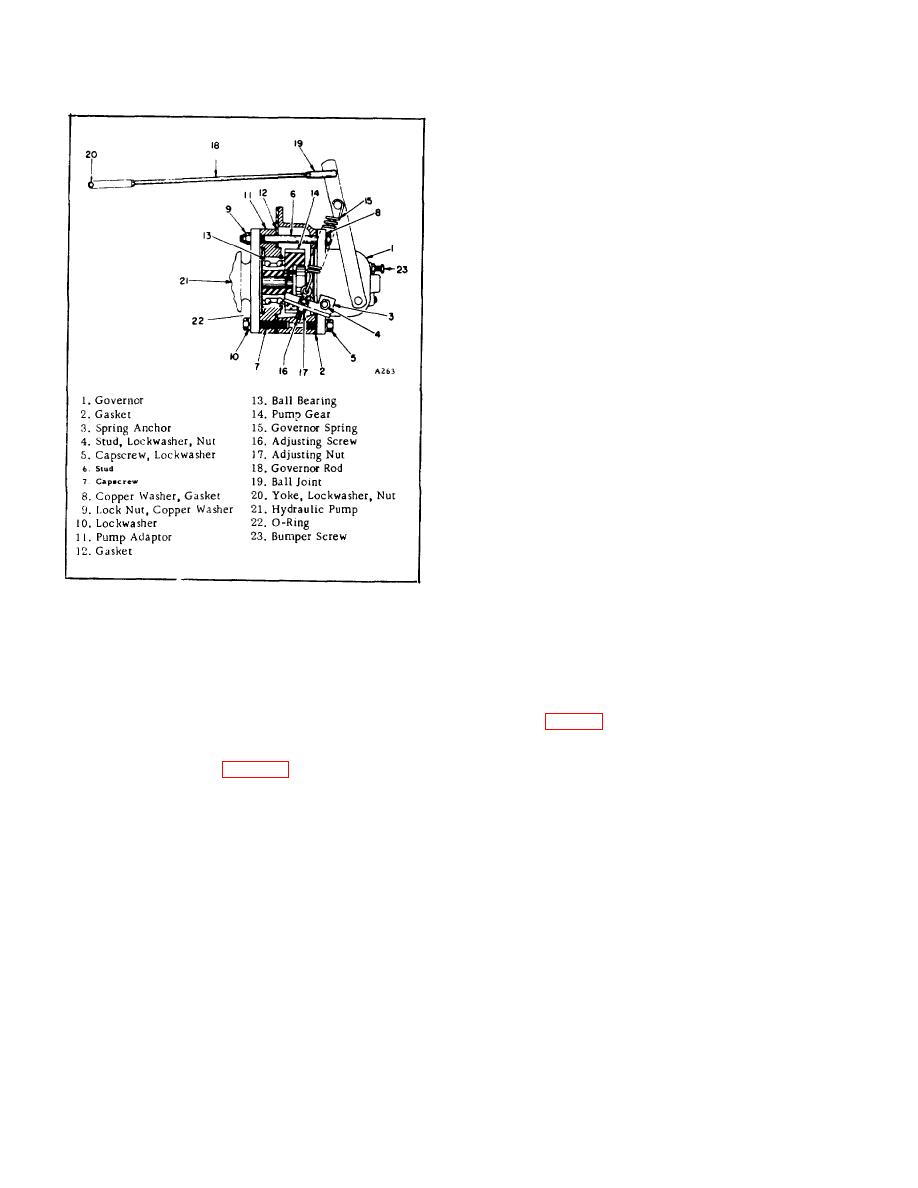

Figure 62

specified sequence. Torque to specification.

Turning the nuts clockwise increases the spring tension

5. Make certain the gasket surfaces are flat and

thus raising the engine speed.

clean, before assembling the oil pan with new gaskets.

Turning the nuts counterclockwise decreases the spring

Tighten screws in accordance with specified limits.

tension. After making the adjustment, be sure to tighten

When engine is assembled and filled with proper oil, set

the two locknuts.

tappets. (Fig. 63) See Specification Listing.

5. Should governor surge at no-load high idle,

INSTALLATION

screw bumper screw (Fig.

eliminated. Do not run bumper screw in far enough to

After engine is placed in the chassis and major

increase speed.

components are installed, perform the following:

C.

SERVICE

The driver must always be tight to the shaft.

The races must be free on the shaft. In assembly of the

governor a space of .004" to .006" is provided between

the driver and the flat race. This is to assure freedom

for movement of the flat race. When servicing the

governor, make sure that both races revolve freely on

the

shaft.

When

the

balls

B-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |