|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

OPERATING INSTRUCTIONS

the load is centered on the arms and that it is well-

about the drive axle A-B. If it tips over sideways, it will

seated against the face of the lifting carriage.

do so at about the line A-C or B-C.

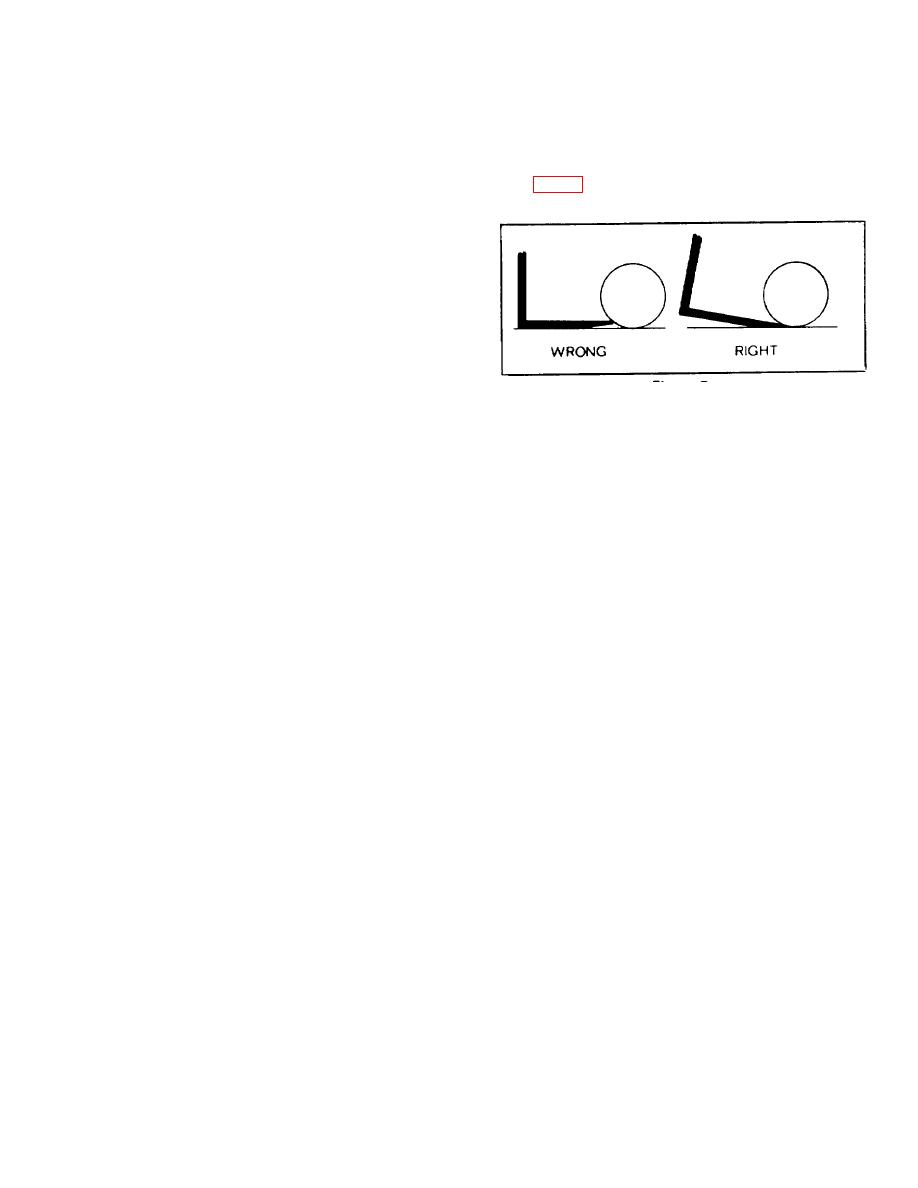

When picking up round objects, first tilt the uprights so

The combined center of gravity, E, is within the

that the forks slide along the floor under the object to be

boundaries of the triangle formed by A, B and C, when

lifted. (Fig. 5)

the upright is vertical. The farther E is from lines A-B,

A-C or B-C the more stable is the truck. As the load and

upright is tilted forward, E moves forward also. This

brings point E closer to line A-B and the truck is less

stable forward. If the load is tilted forward far enough to

move E ahead of line A-B (provided the load does not

slip off the forks), the truck will tip over forward.

As the load is tilted backward, E moves backward and

gets closer to lines A-C and B-C. In this condition side

stability is impaired.

Figure 5.

The most stable condition, therefore, is when the upright

is vertical. It is very important then, when raising a load,

2. Depress the inching pedal. Accelerate the engine

to keep the upright nearly vertical. ONLY BACKTILT

with the accelerator pedal.

ENOUGH TO KEEP THE LOAD FROM SLIPPING OFF

THE FORKS.

3. When sufficient backward tilt of the uprights is

obtained to allow safe handling of the load, move the

B. LIFTING, LOWERING, TILTING

hydraulic lever back to neutral and then move it to the

left position and pull back. At the same time accelerate

The hoist and tilt mechanisms are both actuated by the

the engine until the desired hoist speed is obtained.

same lever. Pull the lever back and the hoist lifts. Push

it forward and it lowers. The tilt mechanism is operated

Never race the engine while hoisting a load. Engine

by pushing the lever to the extreme right, then pulling it

speeds above 2200 RPM will not increase speed of the

back to tilt the uprights back and push it forward to tilt

hoisting mechanism and will only result in excessive

the uprights forward.

wear and damage to the engine. With a little practice

the operator will learn by sound, observation and "feel"

C. LOADING AND STACKING

the maximum efficient hoisting speed.

When the control lever is released, it will automatically

4. When the load has been raised to the desired

return to neutral and stop the hoist or tilt operation.

height, ease the hoist lever to the neutral position and

move the truck to the base of the stack on which the

Lifting speed is controlled by: 1) the speed of the

load is to be placed.

engine, and 2) the extent the control lever is pulled.

Engine speed has no effect on lowering speed.

Although a load may be placed on or removed

1. Move the truck forward until the load arms are

entirely under the load to be lifted. Make certain that

A-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |