|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-242-34

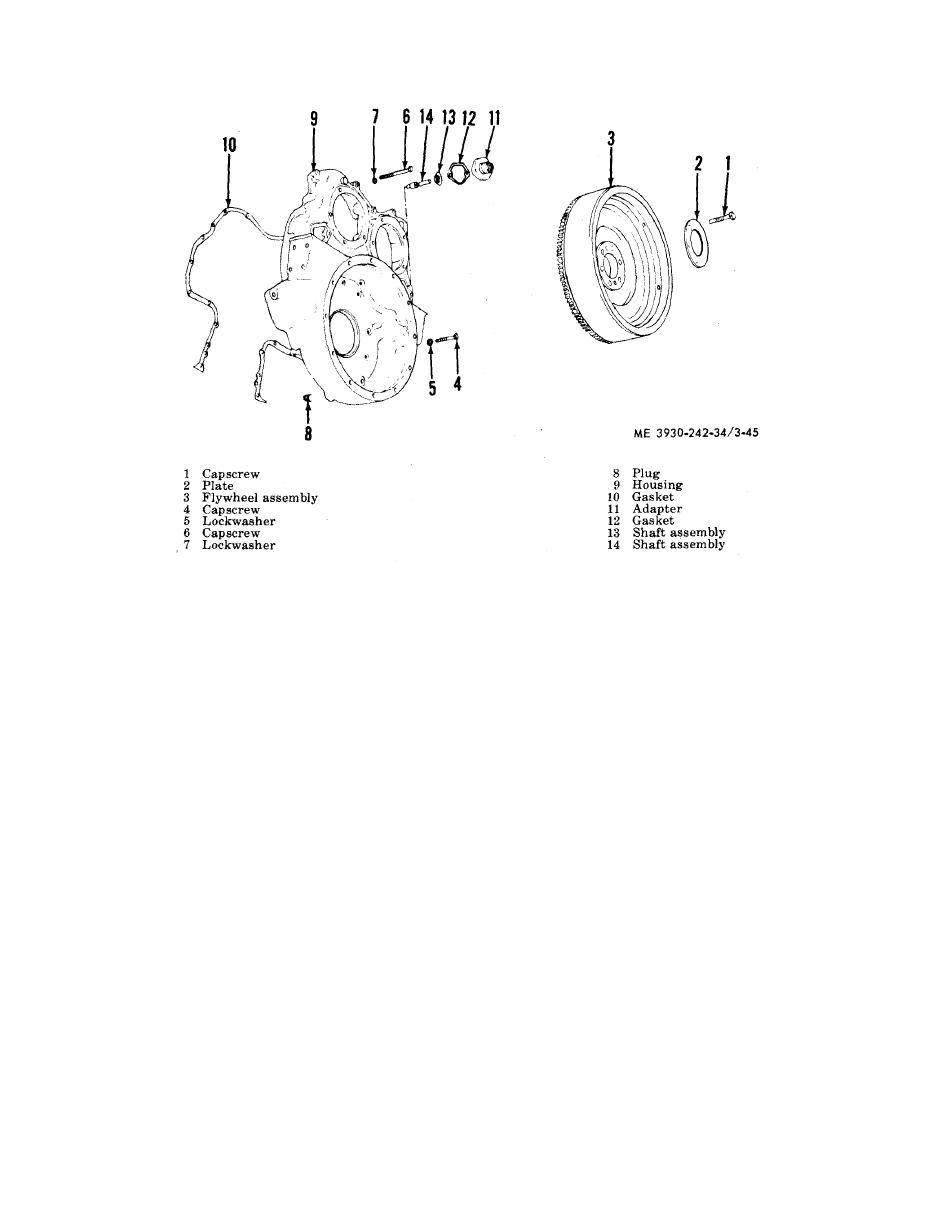

d e s t r o y the original heat treatment. Heat indi-

(3) Remove ring gear from flywheel. B e f o r e

cators of "crayon" which are placed on work and

r e m o v i n g the ring gear from the flywheel, note

melt at a predetermined temperature. Use of

w h e t h e r teeth are chamfered. The replacement

g e a r must be installed so that the chamfer on

one of these "crayons" will insure against over-

t e e t h faces same direction with relationship to

h e a t i n g of the ring gear.

(c) Pick the ring gear up with tongs and

flywheel as on gear that is to be removed. Then

p l a c e in position on flywheel with ring gear

remove ring gear as follows:

(a) Place the flywheel, crankshaft side

chamfer, if any, facing the same direction as the

o n e just removed.

down, on a solid surface or hardwood block

(d) Tap ring gear into place against

w h i c h is slightly less in diameter than the fly-

wheel.

shoulder on flywheel. If ring gear cannot be

(b) Drive the ring gear off the flywheel

t a p p e d into place readily, remove ring gear and

using a suitable drift and hammer. The ring

a p p l y additional heat, heeding the above cau-

tion about overheating.

g e a r may be heated with a torch to facilitate

d . Installation.

r e m o v a l . Work around the circumference of the

ring to avoid binding ring gear on the flywheel.

(1) If a pilot bearing is used in bore of fly-

R e m o v e pilot bearing, if required.

w h e e l and was removed, install bearing. Install

(4) Replace ring gear on flywheel.

new seal ring if one was previously used.

(a) Support the flywheel on a solid flat

( 2 ) Mount flywheel, using lifting tool and

c h a i n hoist, into position against rear end of

surface with ring gear side of flywheel up.

(b) Rest the ring gear on a metal or con-

crankshaft.

(3) While holding flywheel in place by hand,

crete surface and, using a blow torch or

remove flywheel lifting tool and install flywheel

a c e t y l e n e torch, heat ring gear uniformly, keep-

a t t a c h i n g bolts and scuff plate. Tighten bolts to

i n g the blow torch moving around the circum-

1 3 0 - 1 4 0 foot-pounds torque.

ference of the ring gear to avoid hot spots.

(4) Mount a dial indicator on flywheel hous-

Under no circumstances should the ring gear be

ing and check runout of flywheel at clutch con-

h e a t e d over 400 F., as excessive heating may

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |