|

|||

|

|

|||

|

Page Title:

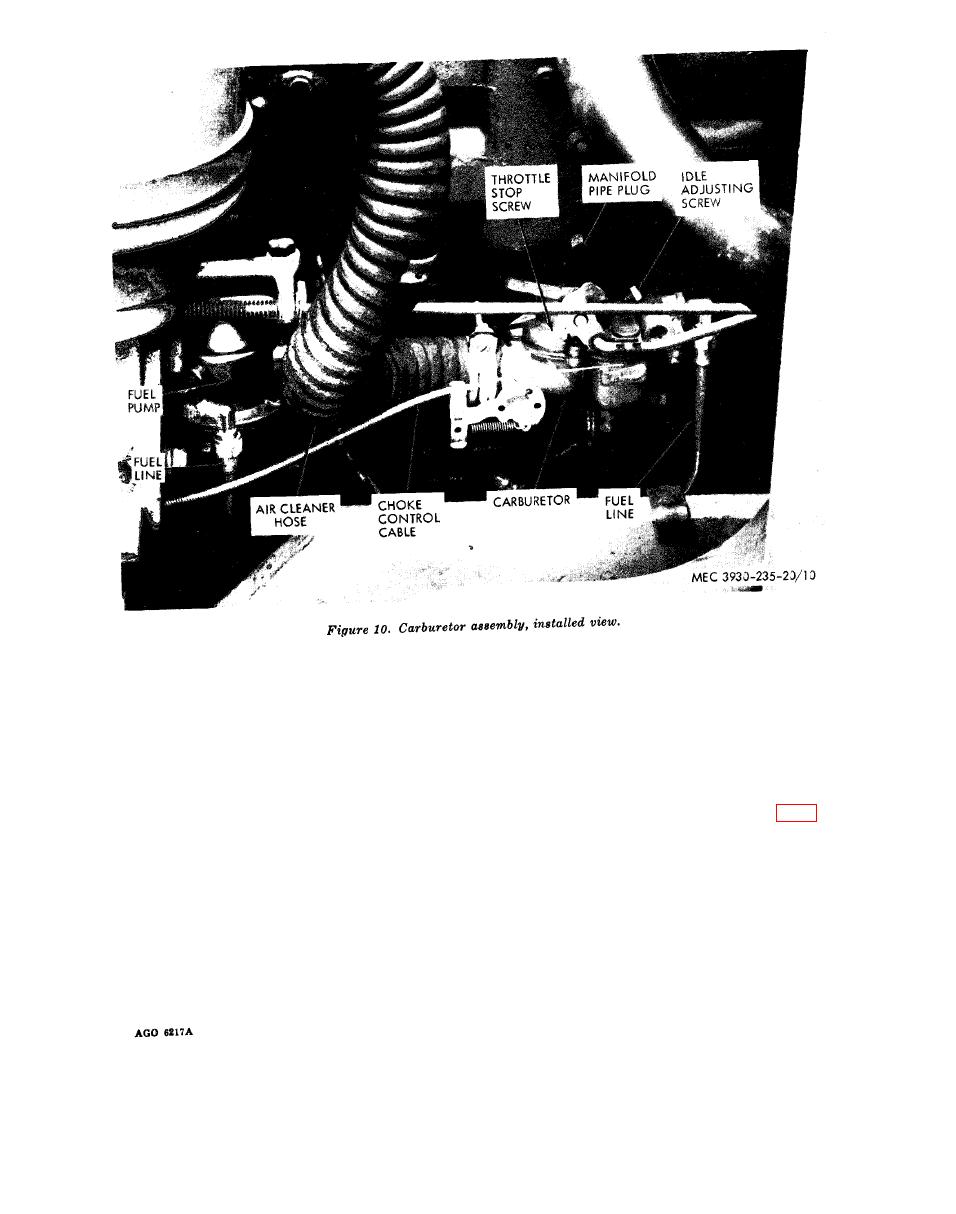

Figure 10. Carburator assmbly, installed view |

|

||

| ||||||||||

|

|

26. Air Cleaner

(d) The reading on the gage is the static

pressure of the fuel pump. Reading

a. Cleaning.

should be between 3 to 4 psi.

(1) Turn air cleaner cup clockwise (fig.

(e) Replace pump if static pressure test

4) then remove cup and air chamber.

shows an underpressure or an over-

Remove air chamber from cup.

pressure reading.

(2) Clean cup and air chamber with SD.

(2) Capacity test. The capacity test meas-

(3) Refill to level indicated in center of air

ures the amount of fuel that the pump

chamber with seasonal OE (fig. 1).

will deliver in excess of fuel needed to

operate the engine at idling speed.

b. Removal.

(a) Attach a T-fitting in carburetor in-

(1) Disconnect air cleaner hose at air

let.

cleaner.

(b) Connect fuel line to T-fitting.

(c) Start engine and not time necessary

(2) Loosen bracket screw, nut, and wash-

to fill a l-quart measure with fuel

er.

from remaining outlet of T-fitting.

(3) Lift out air cleaner.

Adequate fuel delivery is available

when a full quart flows in 1 minute

c. Installation. Reverse procedure in b above.

or less at 500 rpm.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |