|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

29. tropical Areas

cleaner during sandstorms. If necessary, clean

the oil fillercap daily by dipping it several times

In tropical areas, when paint is chipped or

in Solvent, dry cleaning (SD). Make certain

scratched from truck, corrosive action takes

that sand is removed from axles, wheels, steer-

place almost immediately. To prevent this, have

the paint removed with paint remover, sand-

ing spindles, radiator, and brake assemblies.

paper, or sandblasting equipment. Have two

Protect the lift and tilt mechanism from sand.

coats of red lead primer applied and, when dry,

During sandstorms, cover the exposed parts of

have a finishing coat of paint applied.

the lift and tilt cylinder piston rods.

Section V. TROUBLESHOOTING

31. Troubleshooting

30. Purpose

In the troubleshooting chart each symptom

Troubleshooting is the process of locating

of trouble is followed by a list of probable

and correcting malfunctions that may occur

causes and suggested procedure for locating

under normal operating conditions, and it is

and remedying the trouble. Troubles which

the responsibility of the using organization.

cannot be remedied by the operator should be

reported to the proper authority.

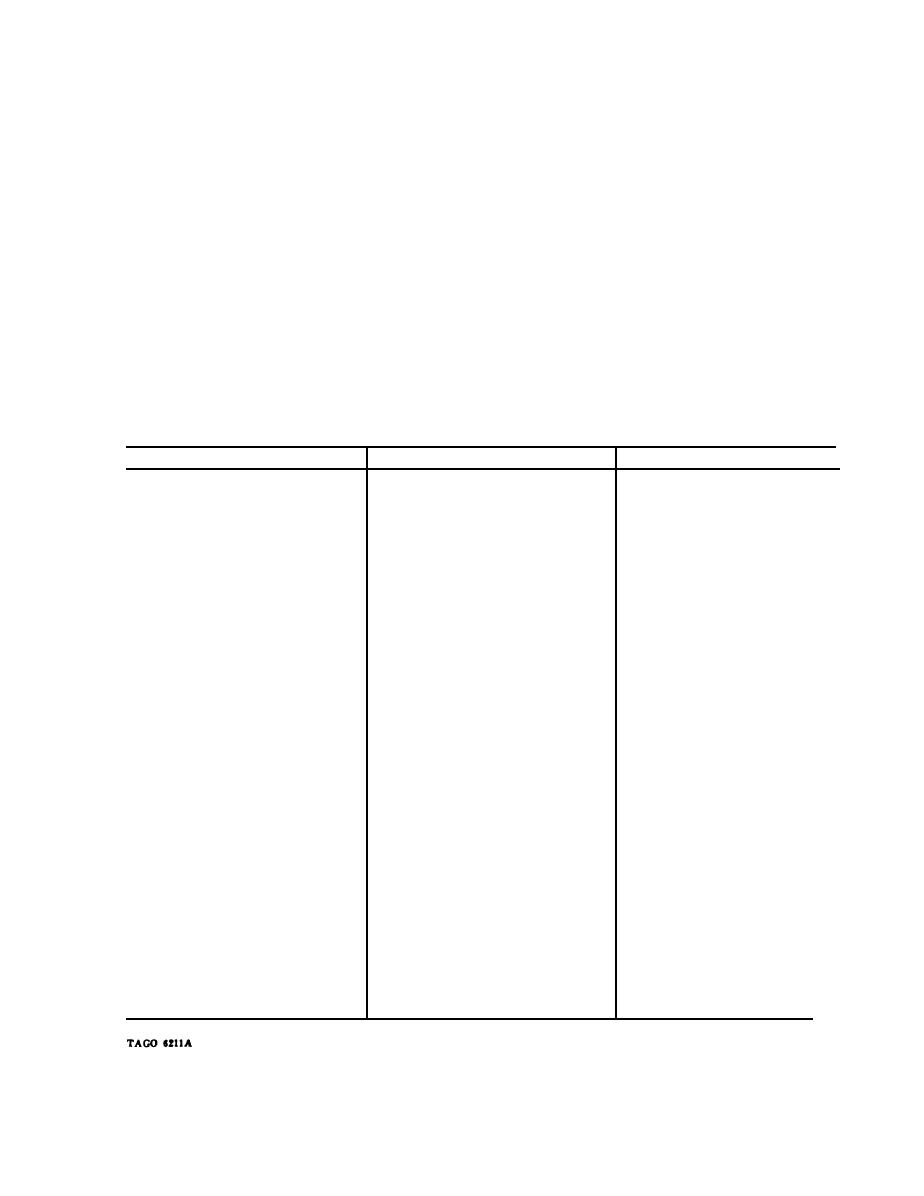

Troubleshooting Chart

Symptom

Probable cause

Corrective action

(a) Notify organizational mainte-

(a) Defective starter system ---------------

1. Engine will not turn when start-

nance personnel.

ing motor is actuated.

(b) Notify organizational mainte-

(b) Mechanical seizure of parts ----------

nance personnel.

(a) Have cable cleaned and tight-

(a) Loose or corroded connections ----

2. Starter will not crank engine.

ened.

(b) Notify organizational mainte-

(b) Battery discharged ----------------------

nance personnel.

(a) Notify organizational person-

(a) Battery discharged -------------------

3. Slow cranking speed.

nel.

(b) Have oil changed to correct

(b) Incorrect crankcase oil viscos-

viscosity.

ity.

(a) Have wires replaced or con-

(a) Loose or disconnected wires in

4. Engine turns over but will not

nections tightened.

ignition system

start.

(b) Fill fuel tank.

(b) Fuel tank empty --------------------

(c) Open throttle and crank en-

(c) Combustion chamber flooded

gine to expel excessive fuel.

with fuel.

(a) Low coolant level ----------------------

(a) Add coolant to radiator. Check

5. Engine overheating.

for leaks.

(b) Loose or broken fan belt --------------

(b) Have organizational mainte-

nance personnel tighten or re-

place belt.

Release parking brake.

Parking brake applied -----------------------

6. Lack of power.

Check oil level and have oil added

Oil low in crankcase ---------------------------

7. Low or no oil pressure.

as necessary.

Check oil level and have oil added

Oil low in transmission --------------------------

8. Truck will not move when trans-

as necessary.

mission controls are engaged.

Low tire pressure -------------------------------

Inflate tires to correct pressure.

9. Hard or irregular steering.

Low oil level in hydraulic tank --------------

Check oil level and have oil added

10. Hydraulic system will not lift or

as necessary.

tilt load or lifts slowly.

17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |