|

|||

|

|

|||

|

Page Title:

10K FORK SIDESHIFT CYLINDERS REPAIR - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

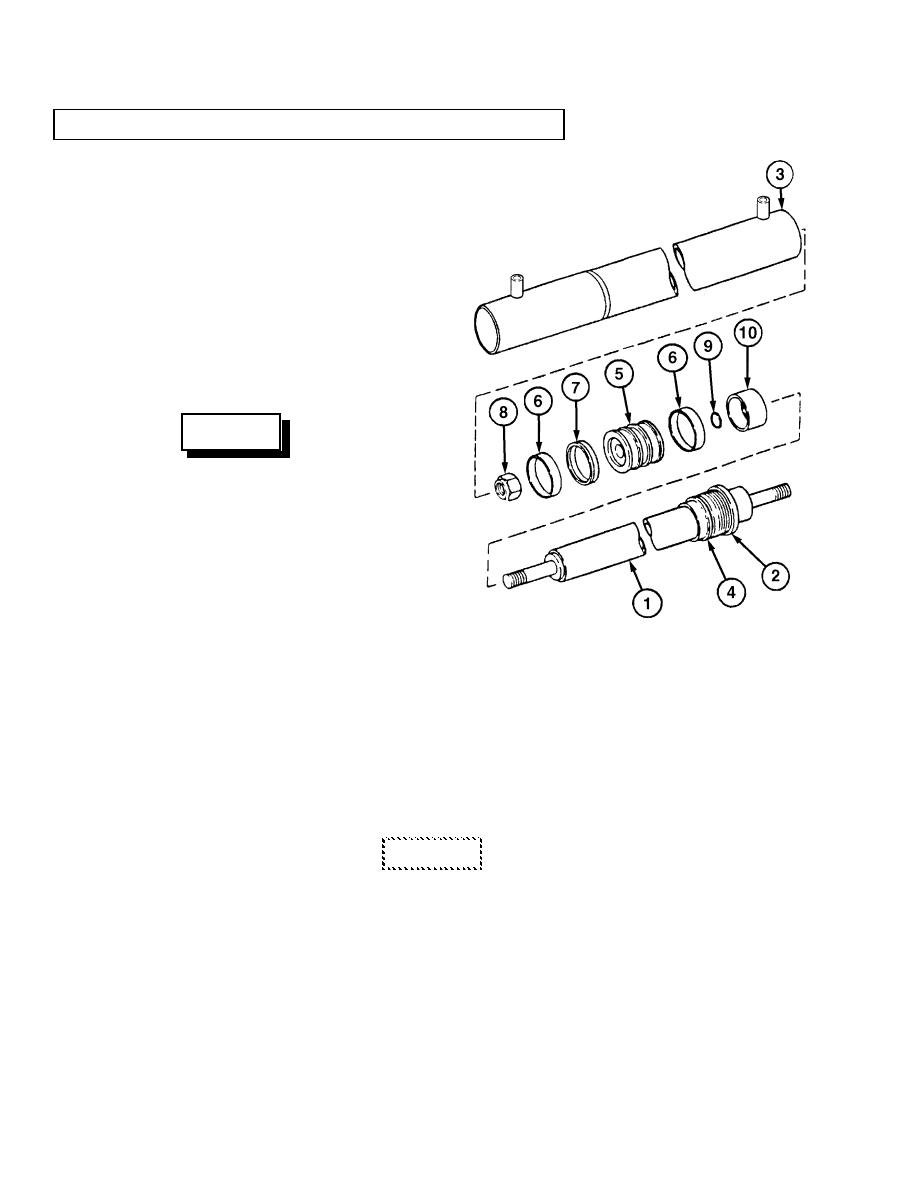

16-20. 10K FORK SIDESHIFT CYLINDERS REPAIR (CONT)

(c)

Install stop tube (10) in rod (1).

(d)

Install gland on rod (1).

(e)

Lubricate piston (5) bore with

hydraulic oil. Install preformed

packing (9) in piston bore.

(f)

Use a cleaning solvent and lint free

rag to clean threads on rod (1) and

nut (8).

(g)

Install piston (5) on rod (1).

WARNING

Adhesives, solvents, and sealing

compounds can burn easily, can give

off harmful vapors, and are harmful

to skin and clothing. To avoid injury

or death, keep away from open fire

and use in a well-ventilated area. If

adhesive, solvent, or sealing

compound gets on skin or clothing,

wash immediately with soap and

TR01376

water.

(h)

Apply sealing compound on threads

of rod (1) and nut (8). Install nut on rod. Tighten nut to 250 lb-ft (339 Nm).

(i)

Place rod (1) and piston (5) as an assembly on suitable supports to prevent damage during

assembly.

(j)

Install two wear rings (6) and one seal (7) on piston (5). Position wear rings so that gaps are

180 degrees apart.

CAUTION

Use care when installing rod and piston assembly. Keep rod in line with cylinder tube to

prevent binding. Failure to follow this precaution will cause part damage.

(k)

Lubricate cylinder tube (3) inner diameter, piston (5) and outside diameter with clean

hydraulic oil.

(l)

Apply sealing compound to threads of gland (2).

(m) Position rod (1) and piston (5) as an assembly in cylinder tube (3).

16-118

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |