|

|||

|

|

|||

|

Page Title:

BOOM ASSEMBLY REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

16-11. BOOM ASSEMBLY REPLACEMENT (CONT)

b. Installation

NOTE

Center of gravity for boom assembly is approximately 9 ft from rear end of boom assembly.

Install a bolt and nut to top-front of outer boom. Install one hook to bolt and other two hooks to top-

rear of outer boom.

WARNING

Before installation of complete boom assembly, remove the countweight. Failure to install the

counterweight will result in the machine being rear end heavy and rear tipping may occur.

Hydraulic oil in the system can be under pressures over 3000 psi (20685 kPa) with the engine OFF.

ALWAYS relieve pressure in hydraulic lines before attempting to remove any component in the

hydraulic system. With engine OFF, move control levers through all operating positions several

times to relieve line pressure. Relieve pressure in hydraulic oil tank by loosening filler cap very

slowly. Failure to follow these precautions could result in serious personal injury.

Boom assembly including boom extend cylinder weighs approximately 4100 lb (1859.72 kg).

Attach suitable lifting device prior to installation to prevent possible injury to personnel.

(1)

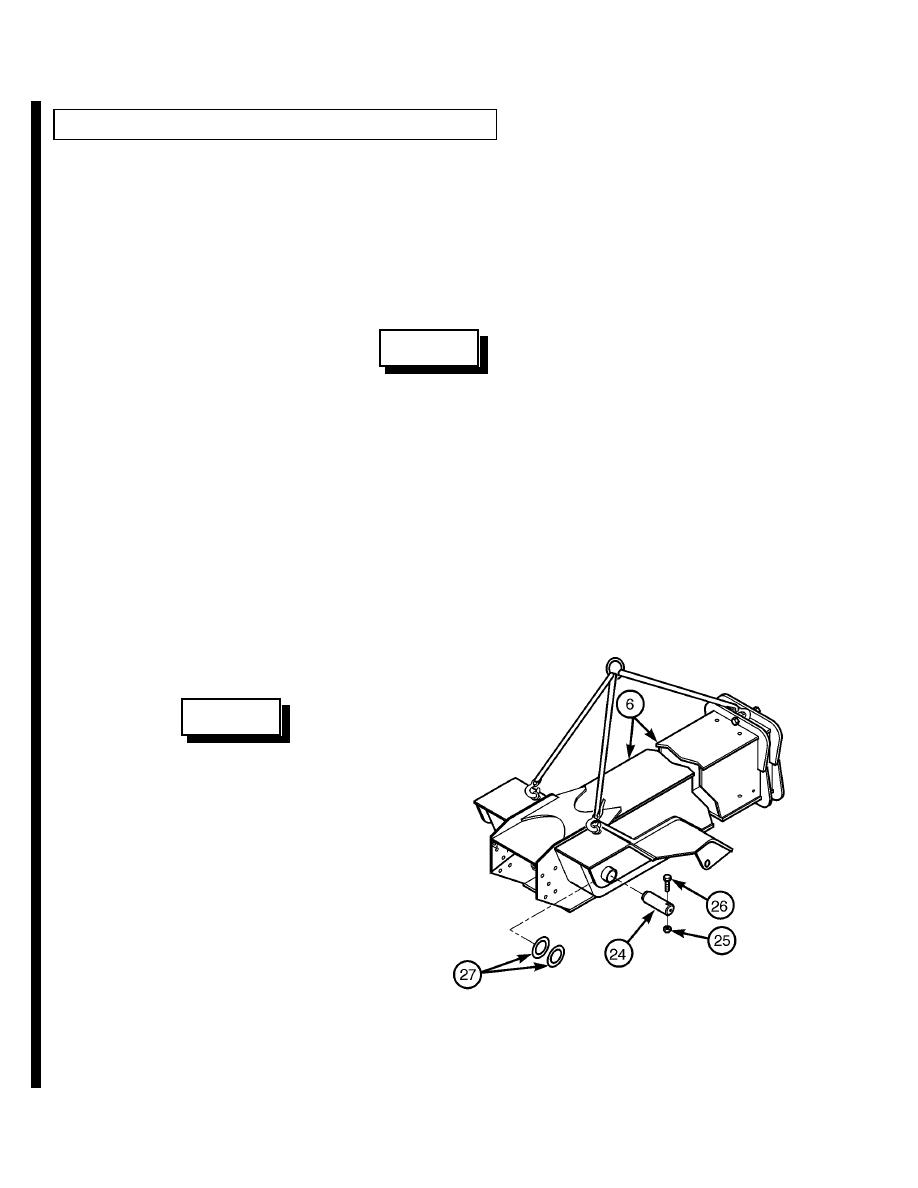

Carefully lift boom assembly (6) into position over vehicle with hoist and sling or other suitable lifting

device. Lower boom assembly as required to align boom pivot pin holes.

WARNING

Adhesives, solvents, and sealing

compounds can burn easily, can give off

harmful vapors, and are harmful to skin

and clothing. To avoid injury or death,

keep away from open fire and use in a

well-ventilated area. If adhesive, solvent,

or sealing compound gets on skin or

clothing, wash immediately with soap and

water.

TR01367

(2)

Position shims (27) between outer boom

section and inside surface of vehicle frame.

Apply anti-seize compound on boom pivot

pin (24) and install pivot pin in boom

assembly (6) and vehicle frame.

16-48

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |