|

|||

|

|

|||

|

Page Title:

DISC BRAKE ASSEMBLY REPLACEMENT/REPAIR |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

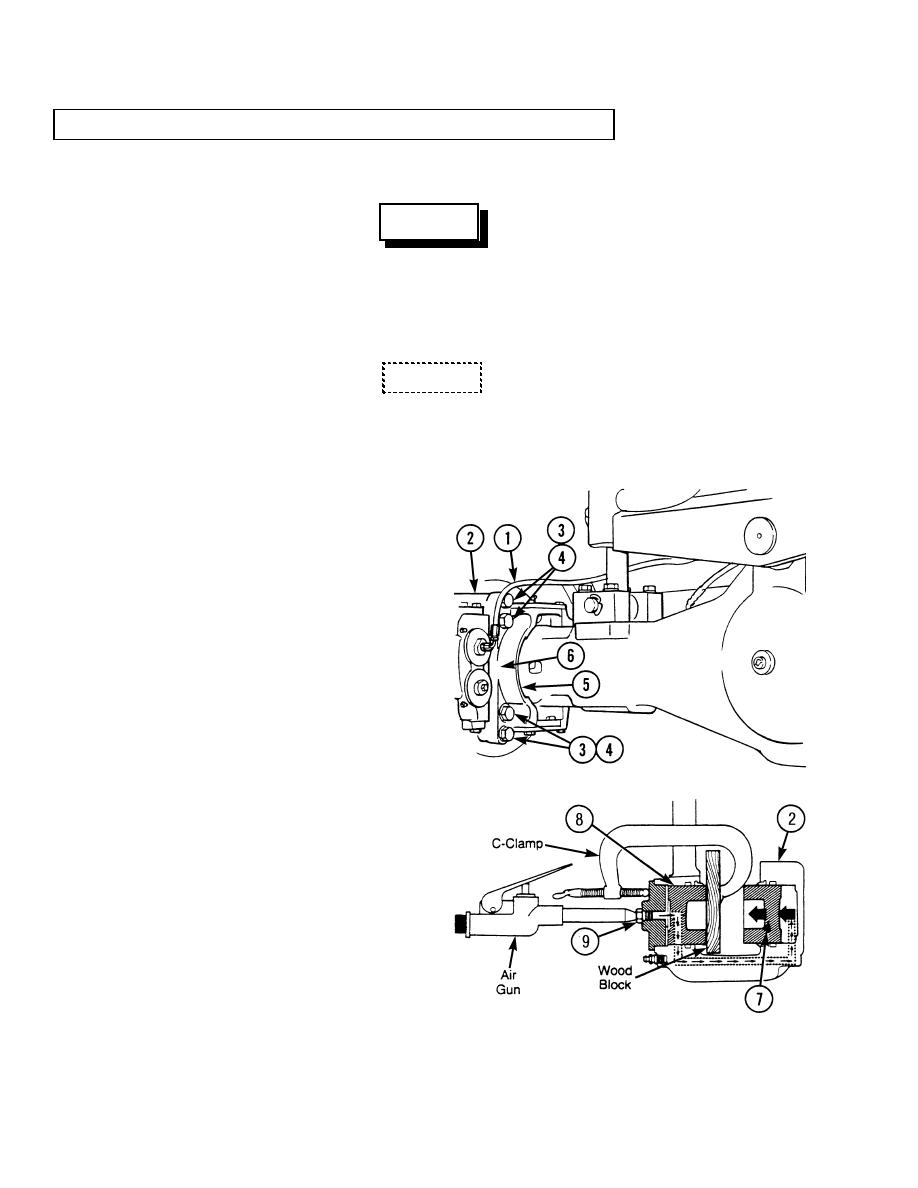

10-3. DISC BRAKE ASSEMBLY REPLACEMENT/REPAIR (CONT)

a. Removal.

WARNING

Always use blocks, jackstands, or other rigid, stable supports when working beneath

raised equipment. Ensure that hoists or jacks are in good condition. Never use frayed,

twisted, or pinched cables. Never use bent or distorted hooks. Failure to follow this

precaution could result in severe personal injury or machine damage.

CAUTION

Wipe the area clean around all hydraulic connections to be opened during removal and

disassembly. Cap oil lines and plug holes after removing lines. Contamination of the

hydraulic system could result in premature failure.

(1)

Tag, mark, and disconnect brake (1)

from brake housing (2).

(2)

Remove four screws (3) and

washers (4) from brake housing (2)

and drive wheel spindle (5).

(3)

Remove disc brake caliper (6) from

drive wheel spindle (5).

(4)

Repeat Steps (1) through (3) for

other disc brakes calipers.

TR00467

b. Disassembly.

(1)

Remove two pistons (7) from brake

housing (2) side opposite the

mounting plate.

(a)

Use C-clamp to hold a 1/2 in.

(12.7 mm) wood block against two

pistons (8) on mounting side of

brake housing (2).

TR00468

10-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |