|

|||

|

|

|||

|

Page Title:

FRONT PLANETARY WHEEL ENDS REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

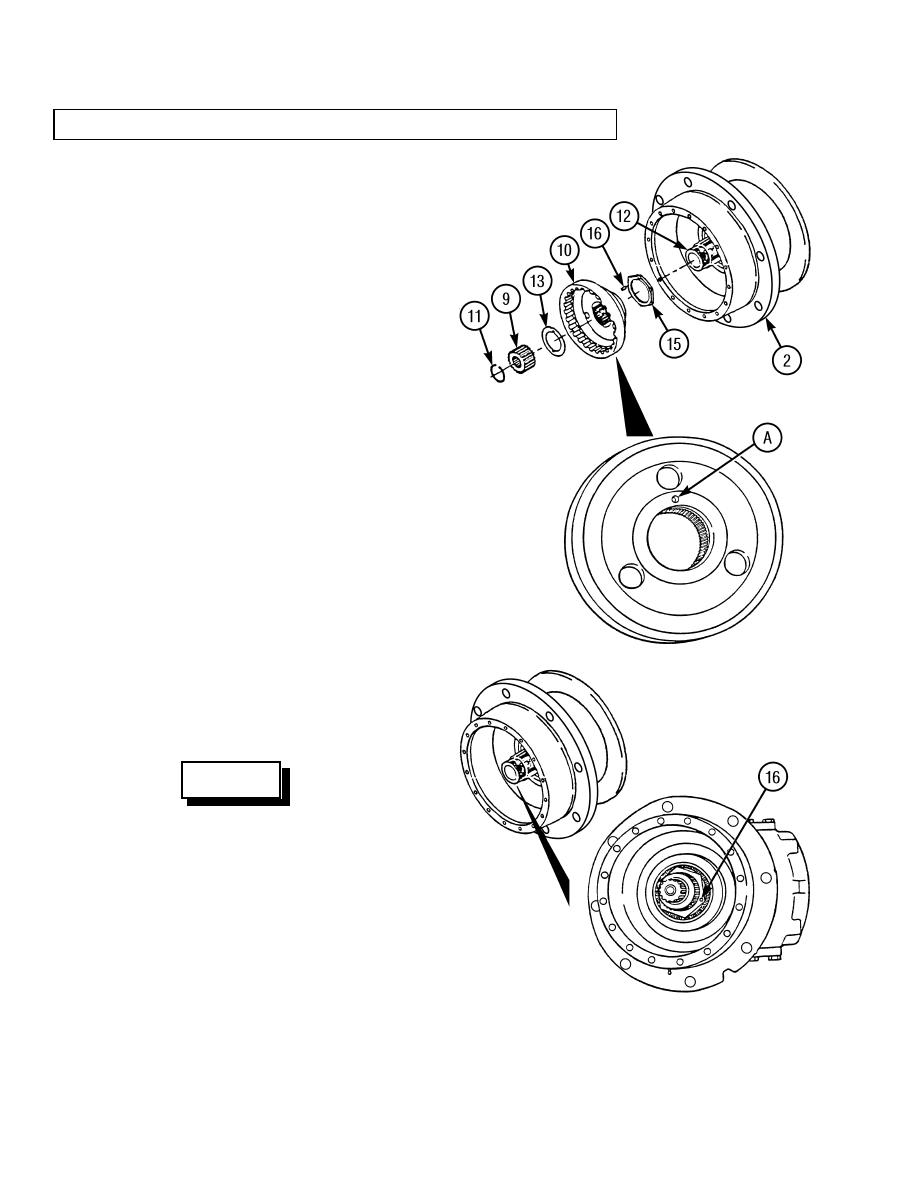

8-6. FRONT PLANETARY WHEEL ENDS REPLACEMENT (CONT)

NOTE

If bearings are to be reused, the

increase in rolling torque should be

1.5 - 2.5 lb-ft (2.03 - 3.39 Nm).

(5)

Install planetary ring gear (10) and

sun gear (9) on wheel hub (2).

(a)

Install dowel pin (16) in nut (15).

(b)

Locate hole (A) on back of planetary

ring gear (10). Orient ring gear with

respect to dowel pin (16) on nut (15).

NOTE

If dowel pin is not aligned with

hole (A) of ring gear, spider

assembly will not fit tight to

wheel hub.

It may be necessary to turn nut (15) to

match hole (A) on back of planetary

ring gear. Hub bearing nut may be

tightened to match dowel pin (16) with

TR00284

planetary ring gear, but torque on hub

bearing nut should not exceed 150 lb-ft

(203.37 Nm).

(c)

Install planetary ring gear (10).

WARNING

Use care when installing snap and

retaining rings. Snap and retaining

rings are under spring tension and

can act as projectiles when released

and could cause severe eye injury.

(d)

Install washer (13), sun gear (9),

and snap ring (11). Tangs on washer

must engage slots in ring gear (10).

TR00285

8-38

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |