|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

4-2. PRINCIPLES OF OPERATION (CONT)

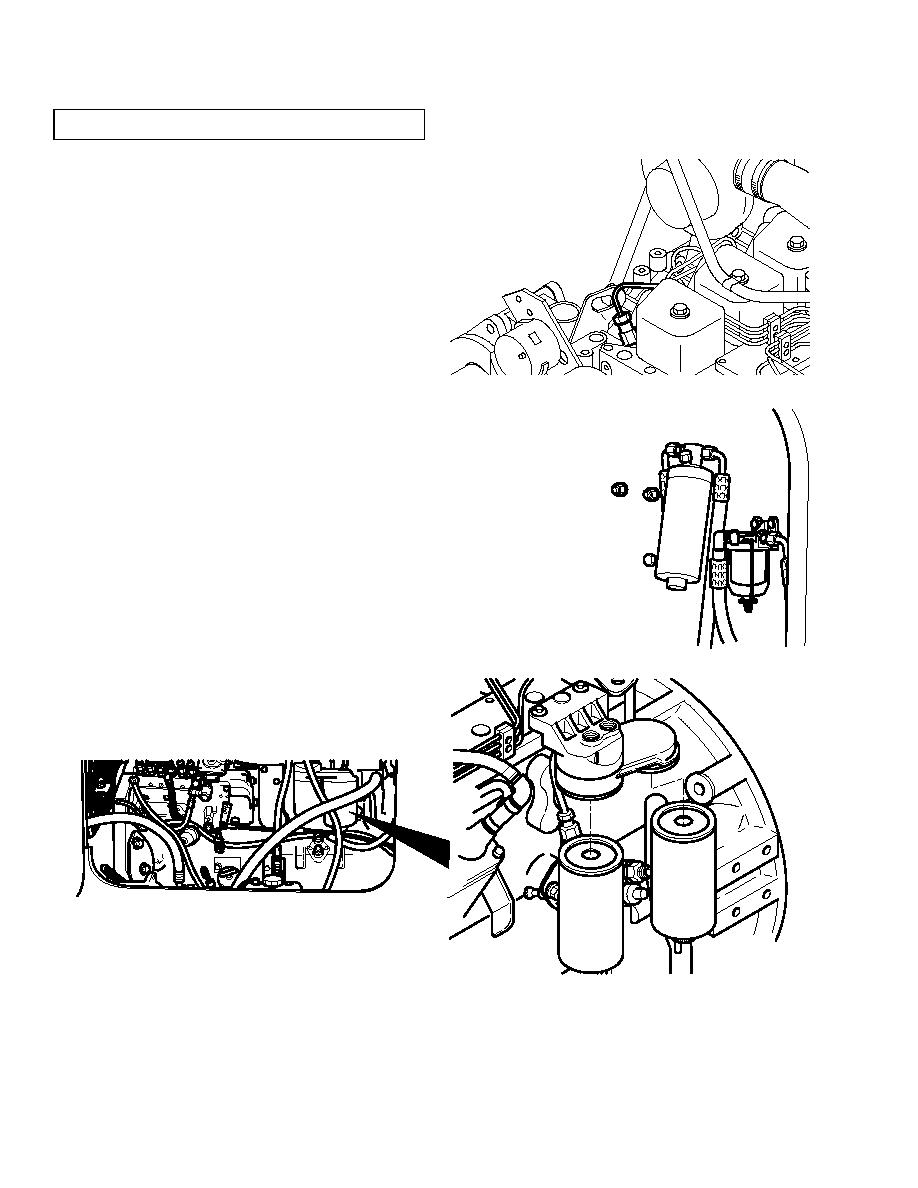

d. Fuel Injectors. The fuel injectors are Robert

Bosch, 17 mm closed nozzle, hole-type injectors.

During the injection cycle, high pressure from the

injection pump rises to operating (pop) pressure

which causes the needle valve in the injector to lift.

Fuel is then injected into the cylinder. A shimmed

spring is used to force the needle valve closed as the

injection pressure drops below the pop pressure to

seal off the nozzle after injection.

TR01397

e. Chassis Mounted Fuel-Water Separator/

Filter. Filtration and separation of water from the

fuel is important for trouble free operation and long

life of the fuel system. Some of the-clearances

between the pump parts are very close. For this

reason the parts can easily be damaged by rust

formation and contaminants. The chassis mounted

separator/filter has two filter elements in a single

glass bowl through which the fuel must flow before

flowing through the outlet. Water and contaminants

settle to the bottom of the sediment bowl and are

removed by removing the drain plug.

TR01398

TR01399

f. Engine Mounted Fuel-Water Separator Filter Unit. The engine mounted fuel-water separator/filter unit

has two replaceable elements. One element of the filter has a valve which can be opened regularly to drain the

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |