|

|||

|

|

|||

|

Page Title:

CAMSHAFT, CAMSHAFT GEAR, AND CAMSHAFT BUSHING REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

3-20. CAMSHAFT, CAMSHAFT GEAR, AND CAMSHAFT BUSHING REPLACEMENT

(CONT)

d. Inspection.

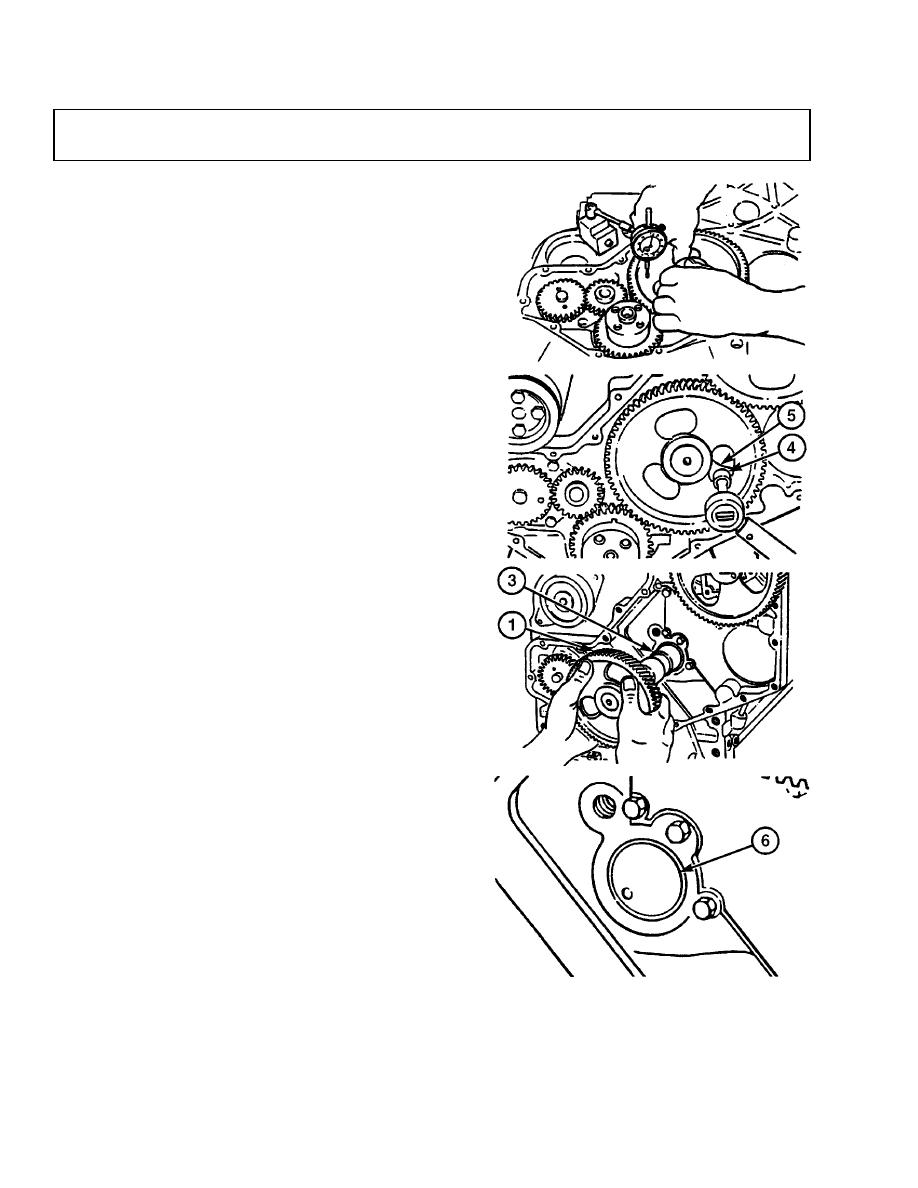

(1)

Inspect camshaft bushing and

camshaft bores in cylinder block.

(a)

Inspect camshaft bushing (6) and

camshaft (3) bores for burrs, scoring,

grooves, and pitting.

(b)

Measure front camshaft bushing (6)

I.D. Acceptable range is 2.1295 -

2.1314 in (54.09 - 54.14 mm).

NOTE

If intermediate and rear camshaft

bores have service bushings

installed, the I.D. dimension must

be within the tolerance specified

above in Step (b).

(c)

Measure intermediate and rear

camshaft bores I.D. Acceptable bore

I.D. range is 2.1295 - 2.1314 in.

(54.09 - 54.14 mm). If bores are

worn beyond this specification, the

cylinder block must be machined

and service bushings installed, or

the cylinder block must be replaced.

Refer to Depot level maintenance.

NOTE

If new valve tappets are being

installed, the camshaft and

camshaft bushing must be replaced.

(2)

Inspect camshaft (3).

(a)

Inspect fuel lift pump lobe, valve

lobes and camshaft bearing journal

for cracking, pitting, or other

defects.

(b)

Measure bearing journal diameter.

TR01774

Minimum allowable diameter is

2.1245 in. (53.962 mm).

3-128

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |