|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

(d)

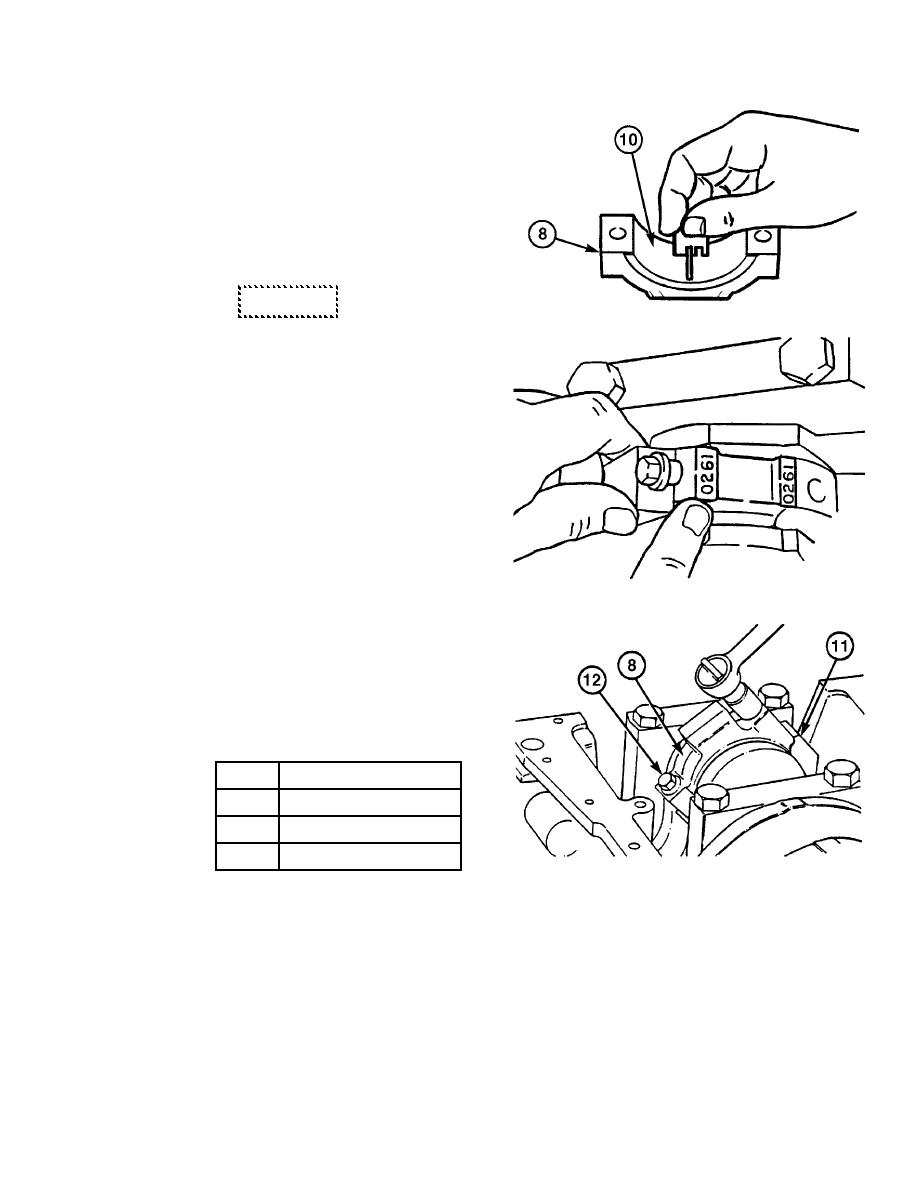

Put new lower bearing half (10) in

connecting rod cap (8). Bearing tabs

must be in the tab grooves of the rod

cap.

(e)

Put plastigage on the surface of the

lower half of connecting rod

bearing (11).

CAUTION

The four digit number stamped on

the connecting rod and the rod cap

must match and be facing the oil

cooler side of the engine. Connecting

rod and cap are machined as a set

and must be kept that way. Failure

to install matched sets could result

in premature engine damage.

NOTE

Do not reuse connecting rod screws.

(f)

Apply lubricating oil to threads of

connecting rod screws (12) then

install connecting rod cap (8) and

screws on connecting rod (11).

Tighten screws finger tight.

(g)

The connecting rod screws (12) must

be tightened evenly in a series of

three steps. The torque value for

each step is shown in this chart.

Step

Torque Value

1

26 lb-ft (35.25 Nm)

2

50 lb-ft (67.79 Nm)

3

73 lb-ft (98.97 Nm)

TR01177

3-69

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |