|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

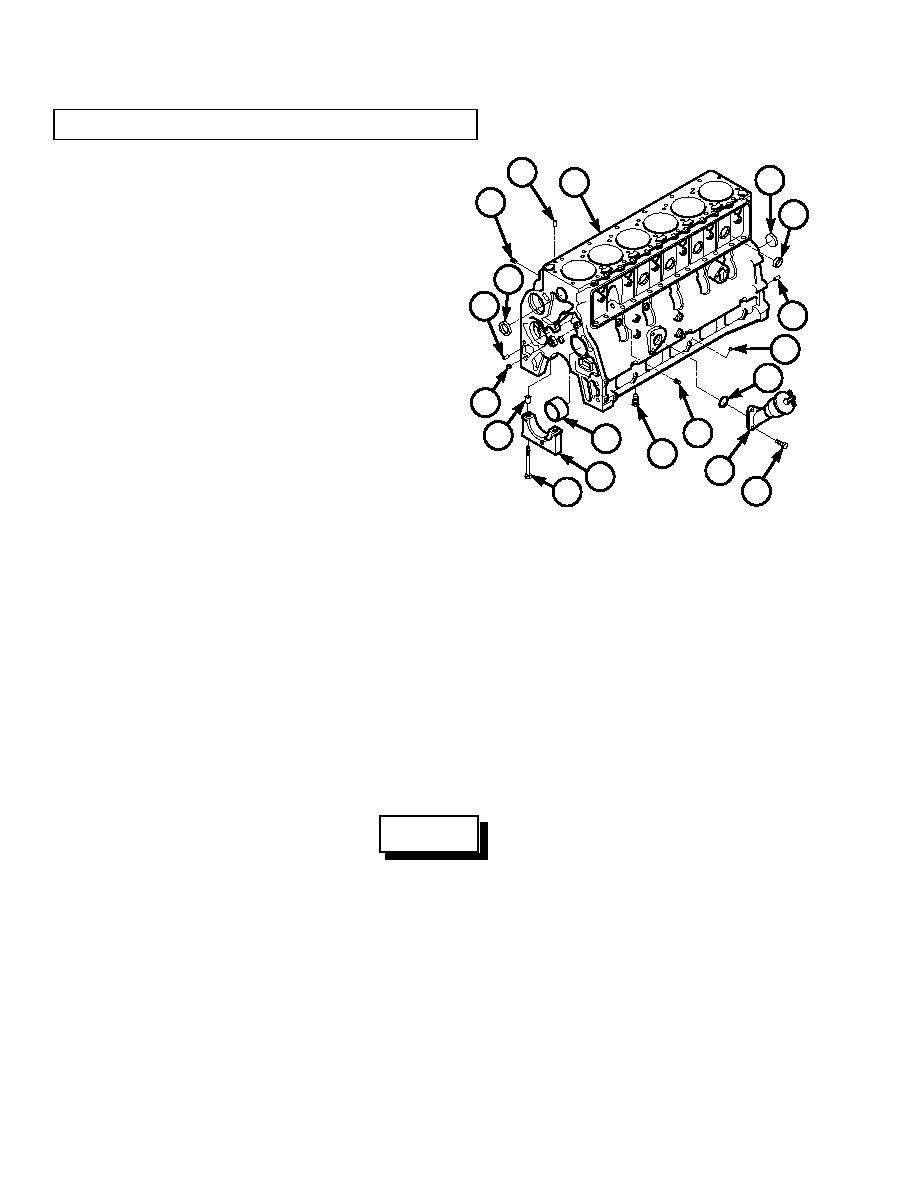

3-6. CYLINDER BLOCK REPLACEMENT (CONT)

(3)

Inspect piston cooling nozzles (19)

13

2

for restricted oil passages or

3

damage. Clean clogged passages

5

8

using fine, soft wire. Replace nozzles

if condition is in doubt.

d. Installation.

7

14

(1)

Install parts (12 through 19) on

12

cylinder block (3).

15

NOTE

11

When installed, piston cooling

6

nozzles must be flush with or

slightly below bearing saddle

4

18

1

surface.

19

10

17

(a)

Install six piston cooling

9

16

nozzles (19) in cylinder block (3).

TR01682

(b)

Install 14 dowel pins (18), bearing

caps (17), and 14 bolts (16) on

cylinder block (3).

(c)

Install two expansion plugs (15) in cylinder block (3).

(d)

Install dowel pins (14) and dowel pins (13) in cylinder block (3).

(e)

Install two bearing sleeves (12) in cylinder block (3).

(2)

Install preformed packing (11), oil filler pipe (10), and two screws (9) on cylinder

block (3).

(3)

Install six cup plugs (7) and four cup plugs (8) in cylinder block (3) coolant passages.

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors,

and are harmful to skin and clothing. To avoid injury or death, keep away from open fire

and use in a well-ventilated area. If adhesive, solvent, or sealing compound gets on skin

or clothing, wash immediately with soap and water.

(a)

Apply a bead of sealing compound to entire circumference of each cup plug (7 and 8).

(b)

Install cup plugs (7 and 8) with convex side out until outer edges are flush with countersink in

cylinder block (3).

3-34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |