|

|||

|

|

|||

|

Page Title:

EXCESSIVE DRIVELINE NOISE - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

WARNING

Differential and ring gear weigh approximately 100 lbs (45.4 kg).

Attach suitable lifting device prior to removal to prevent possible

injury to personnel.

No-spin differential contains compression springs under

pressure. Failure to use a retaining bolt or other means of

restraint can cause injury to personnel when removing

no-spin differential.

Use care when removing snap and retaining rings.

Snap and retaining rings are under spring tension and can

act as projectiles when released, and could cause severe

eye injury.

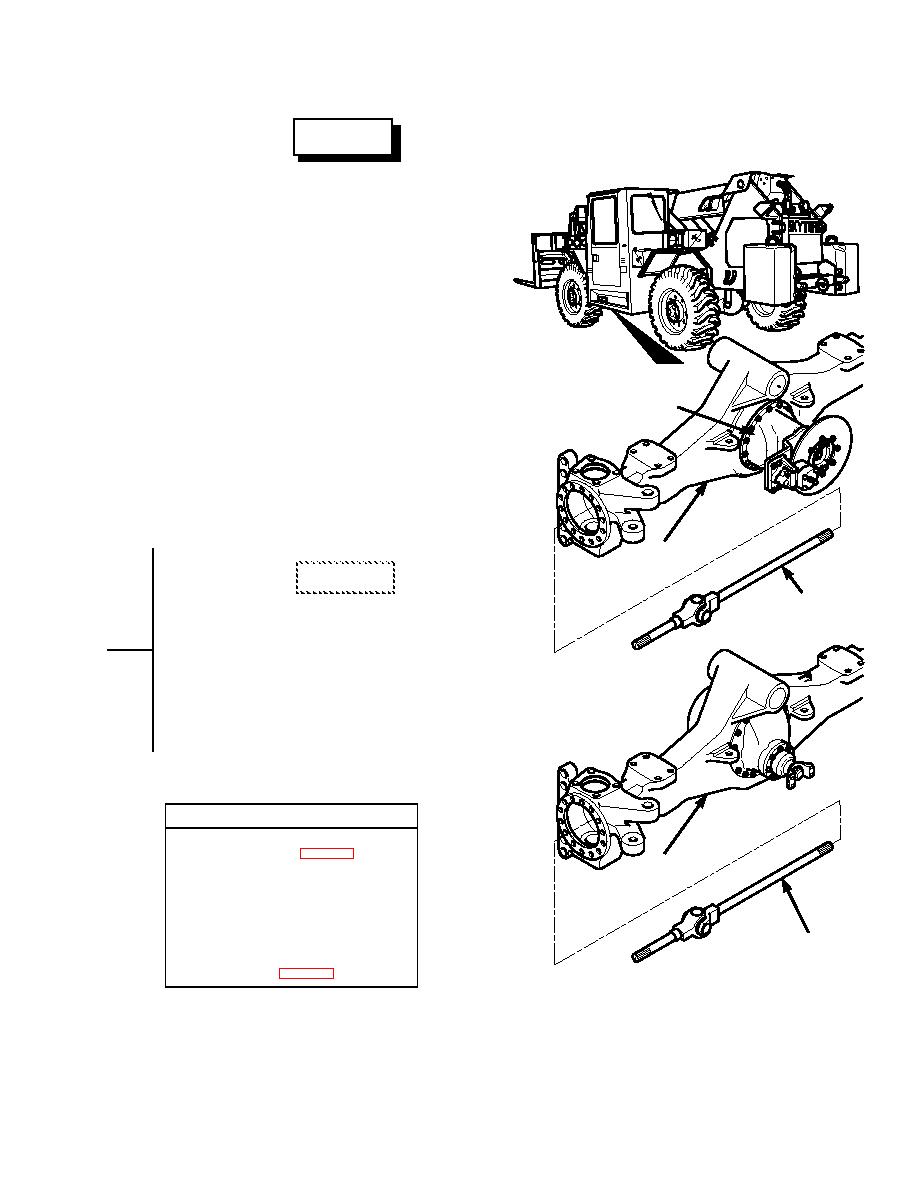

FRONT

Compressed air used for cleaning purposes will not exceed 30 psi

DIFFERENTIAL

(207 kPa). Use only with effective chip guarding and personal

ASSEMBLY

protective equipment (goggles/shield, gloves, and so forth).

Adhesives, solvents, and sealing compounds can burn easily,

can give off harmful vapors, and are harmful to skin and

clothing. To avoid injury or death, keep away from open fire

and use in a well-ventilated area. If adhesive, solvent, or

sealing compound gets on skin or clothing, wash immediately

with soap and water.

AXLE

HOUSING

CAUTION

AXLE

SHAFT

Wipe area clean around all hydraulic connections to be

opened during removal. Cap oil lines and plug holes after

removing lines. Contamination of the hydraulic system could

result in premature failure.

REAR

Ring gear must be heated before installation. Failure to heat ring

gear before installation could cause damage to differential case

DIFFERENTIAL

half because of tight fit.

ASSEMBLY

Spacing between four initially installed screws must be even to

prevent uneven pressure on case halves when torquing.

Failure to do so could cause component failure.

VISUAL INSPECTION

(1) Remove front and/or rear axle shafts

from axle housing (Para 8-5 and 9-5).

AXLE

(2) Visually inspect shafts for bends and

HOUSING

breaks.

(a) If axle shafts are free from signs of

bends and breaks, go to Step 2 of

this fault.

AXLE

(b) If axle shafts show bends and

breaks, replace the shafts as

SHAFT

necessary (Para 8-5 and 9-5).

2-41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |