|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-20-2

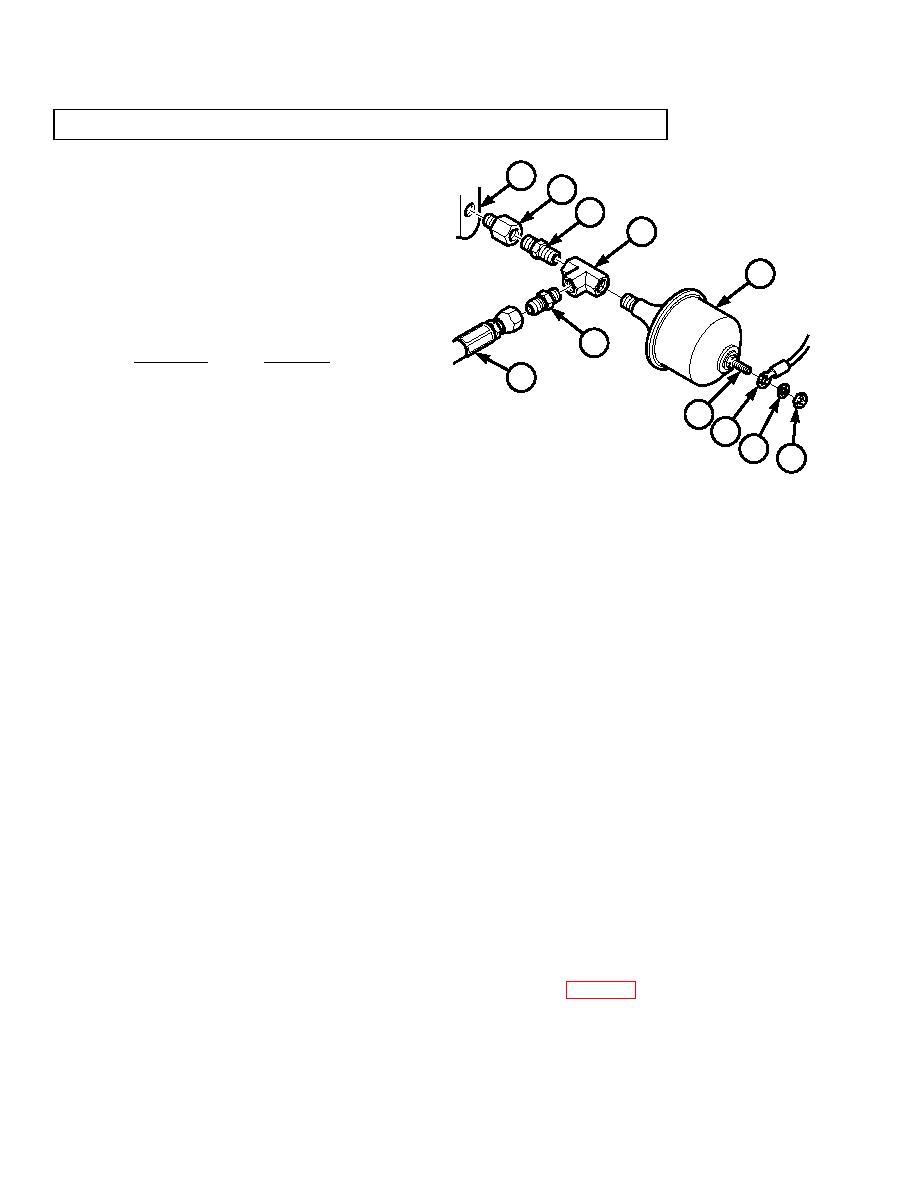

8-35. ENGINE OIL PRESSURE SENDER TEST/REPLACEMENT (CONT)

NOTE

6

11

The 0 psi reading should be read on a

10

decreasing pressure. The 40 psi reading should

7

be read on an increasing pressure.

(4)

Start engine (TM 10-3930-673-10) and

4

observe both STE/ICE oil pressure readout

and multimeter. Sender (4) should show the

following resistance readings:

9

Oil Pressure

Resistance

0 psi

227-257 ohms

8

40 psi

92-114 ohms

5

3

(5)

Replace engine oil pressure sender (4) if

2

resistance requirements are not met

1

(perform b. Removal and c. Installation

TR0054

below).

(6)

Install electrical wire (3) on engine oil

pressure sender (4) with lockwasher (2) and nut (1).

b. Removal.

(1)

Remove nut (1) and lockwasher (2). Tag, mark, and disconnect electrical wire (3) from engine oil pressure

sender (4). Discard lockwasher.

(2)

Remove engine oil pressure sender (4) from tee (7).

(3)

Tag, mark, and remove hose (8) from adapter (9).

(4)

Remove adapter (9) from tee (7) and tee from nipple (10).

(5)

Remove nipple (10) and adapter (11) from engine block (6).

c. Installation.

(1)

Apply sealing compound on threads of adapter (11) and nipple (10) and install adapter and nipple in engine

block (6).

(2)

Apply sealing compound on threads of adapter (9) and tee (7).

(3)

Install tee (7) on nipple (10) and adapter (9) in tee.

(4)

Apply sealing compound to threads of engine oil pressure sender (4) and install sender in tee (7).

(5)

Install electrical wire (3) on engine oil pressure sender (4) with lockwasher (2) and nut (1).

NOTE

Follow-on Maintenance: Connect negative battery cable (Para 8-44).

END OF TASK

8-100

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |