|

|||

|

|

|||

|

Page Title:

EMERGENCY STEERING PUMP DOES NOT OPERATE - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-20-1

WARNING

Hydraulic oil in system can be under pressures over 3000 psi (20685 kPa) with engine OFF. Always relieve pressure in hydraulic

lines before attempting to remove any component in hydraulic system. With engine OFF, starter switch in RUN position, and

MLRS attachment on ground, move control levers through all operating positions several times to relieve live pressure. Relieve

pressure in hydraulic oil tank by loosening filler cap very slowly. Failure to follow these precautions could result in serious

personal injury.

At operating temperatures, hydraulic oil is hot and under pressure. Hot oil is hot and under pressure. Hot oil can cause injuries.

Allow hydraulic oil to cool before disconnecting any hydraulic lines.

CAUTION

Wipe area clean around all hydraulic connections to be opened during removal and disassembly. Cap oil lines and plug holes after

removing lines. Contamination of hydraulic system could result in premature failure.

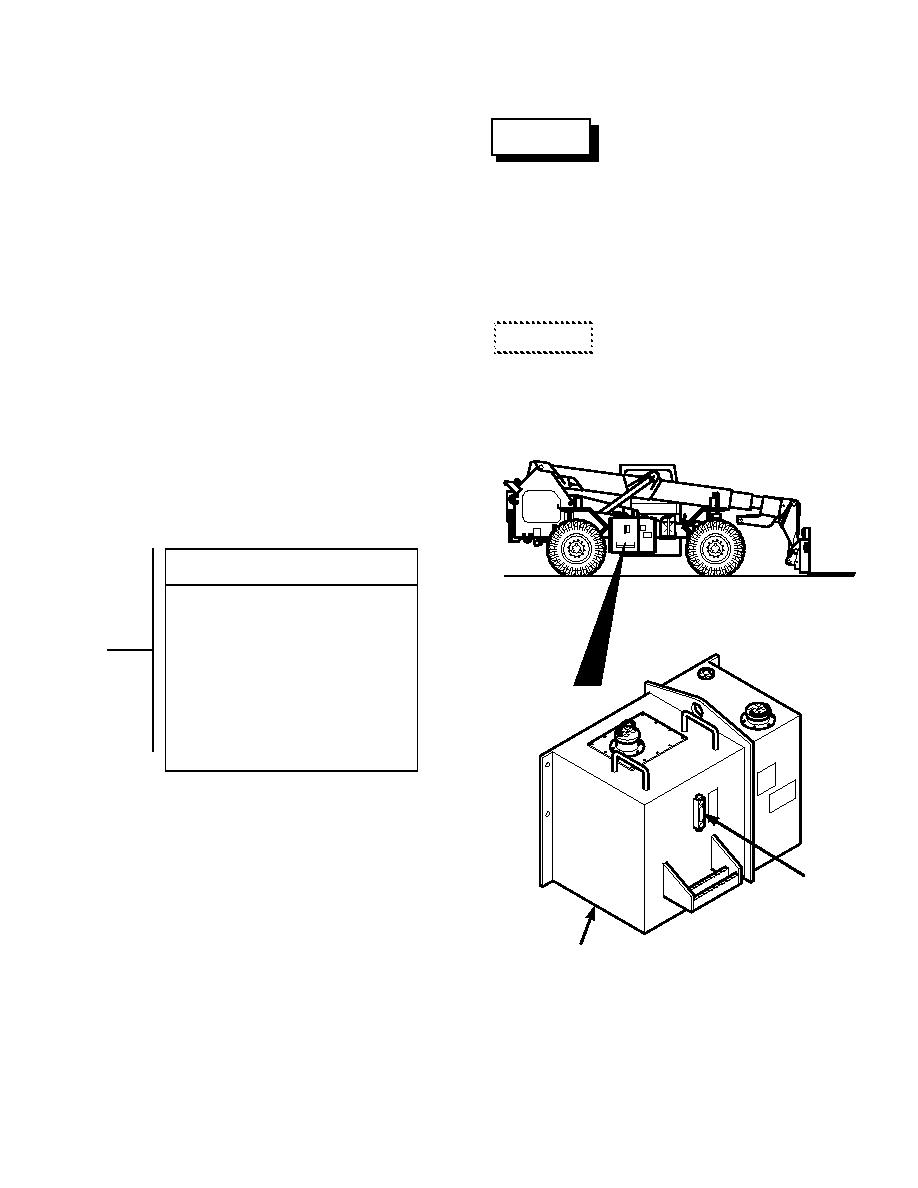

HYDRAULIC OIL LEVEL

VISUAL INSPECTION

(1) Visually inspect hydraulic oil level gage

to determine if tank is filled to proper

level.

(2) Hydraulic oil should be visible between

ADD and FULL marks.

(a) If hydraulic oil is visible between

ADD and FULL marks, go to

Step 2 of the fault.

(b) If hydraulic oil is not visible, inspect

tank for leaks. Then fill tank to

FULL mark with hydraulic oil

(Para 18-2).

HYDRAULIC

O

IL LEVEL GAGE

HYDRAULIC OIL TANK

TR01283

2-859

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |