| |

TM 10-3930-671-24

Lift Chain (Fork Height) Adjustment

NOTE

It is important to make the lift chain

adjustment check with a rated load to

be sure that the chains are stretched

to their maximum length.

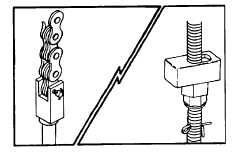

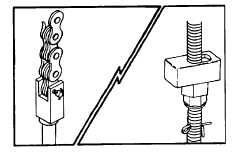

Figure 2. Typical view of chain anchors.

The lift chains are mounted to the chain anchors on the

lift carriage and at the chain anchor rods near the lift

cylinder piston head. The lift chains can be adjusted by

loosening or tightening the chain anchor nuts.

Lift chains should be adjusted to provide equal tension in

each strand of chain. Lift chains are correctly adjusted if

the lower fork carriage rollers reach their end (lowest)

position approximately 0.50 inch (13 mm) from the lower

edge of the inner rail. This also positions the bottom of

the forks the same (equal) distance above the floor.

1.

To check this dimension, raise the carriage to a

height that exposes several inches of the inner

rail at the roller path. Apply a layer of grease to

the roller path on the inner rail. Lower the

carriage, pick up a rated capacity load, tilt the

upright back slightly, and raise the load until the

carriage rollers have passed over the greased

area. Lower the load completely and remove the

load from the forks. Raise the carriage again to

expose the inner rail. You can now check the

roller path pattern in the grease and determine

the correct adjustment of the chains.

2.

Adjust lift chains as necessary.

3.

Inspect the lift chain anchors at both ends of

chain.

Be sure both nuts, for each chain anchor, are in place.

Be sure there is a cotter pin in the end of

each anchor.

4.

As an alternate check procedure, the lift carriage

chains should be adjusted so that the bottoms of

the forks are 0.50 inch (12.1 mm) above the

floor.

Lift Chain Inspection and Measurement for Wear

WARNING

Do not attempt to repair a worn chain.

Replace worn or damaged chain or

injury to personnel and damage to

equipment could result.

1.

Inspect the lift chains every truck PM (50-250

hours).

When

operating

in

corrosive

environments, inspect the chains every 50

hours.

2.

During inspection, check for the following chain

conditions:

•

Rust and corrosion

•

Cracked plates

•

Raised or turned pins

•

Tight joints

•

Wear, e.g. worn pins or holes

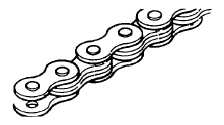

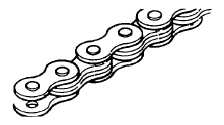

Figure 3. Illustration of typical chain wear and damage.

3. When the pins or holes become worn, the chain

becomes longer. When a section of chain is 3

per cent (%) longer than a section of new chain,

the chain is worn out and must be discarded.

4. Chain wear can be measured by using a chain

scale or a steel tape measure. When checking

chain wear, be sure to measure a segment of

chain that moves over a sheave.

F-499

|