| |

TM 10-3930-671-24

12.1. Counterweight Maintenance

Maintenance - General................................................................... F-487

Counterweight Removal ................................................................. F-487

Counterweight Mounting ................................................................ F-488

Counterweight Removal ................................................................. F-489

Counterweight Inspection............................................................... F-492

Counterweight Installation .............................................................. F-493

Maintenance-General

The counterweight must be maintained in good condition

and securely attached to the lift truck. Because of its

heavy weight and bulky mass, the counterweight must be

carefully supported and handled. Store at floor level in a

stable position to be sure it will not fall or tip, causing

either damage or injury.

Do not operate a lift truck or handle loads with the

counterweight removed. Failure to follow this message

can result in severe injury or death.

Counterweight Removal

Counterweights can be removed by one of two methods:

1)

Using a hoist or overhead crane.

2)

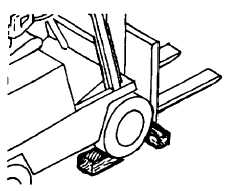

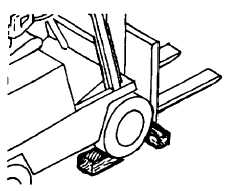

Using another lift truck as a hoist.

All tools and lifting components used in these procedures

must be in good condition, meet the load requirements,

and have OSHA approval labels when required.

NOTE

Prior to performing this service procedure, it is

recommended that you first:

•

Park truck on a solid, level surface.

•

Lower forks or attachment fully down.

•

Put all controls in neutral, apply the

parking brake, and turn key switch OFF.

Minimum Tools Required

•

Wheel blocks

• Eye bolts and lifting chains, sling, or

spreader bar

• Torque wrench, 0-1000 lb-ft (0-1356 N-m)

capacity

• Overhead hoist with adequate capacity

Attach lifting device to counterweight prior to removing

mounting bolts. Do not remove with blocks under

counterweight supporting truck. Failure to follow these

procedures as shown in this manual can result in severe

injury or death.

NOTE

Use lifting hooks with safety latches to prevent hook from

slipping from the lifting eye.

Refer to Section 2. 1, Service Specifications, for

information on counterweight weights.

Put chocks at the drive wheels, as directed.

F-487

|