| |

TM 10-3930-671-24

3.

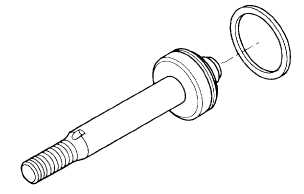

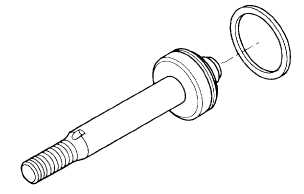

Carefully pull the rod and piston assembly from

the cylinder barrel.

The use of compressed air to blow the piston out of the

barrel is not recommended. High-pressure air can result

in piston and rod being ejected at high velocity

(explosively), causing severe injury to personnel and

property damage.

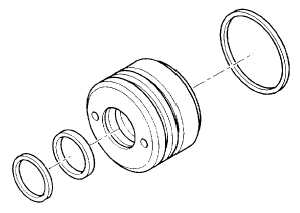

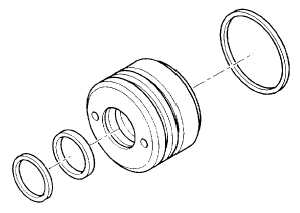

4.

Remove both sets of piston seals and back-up

rings. Discard old seals.

5.

After cleaning and inspection (see below), install

new seals and back-up rings.

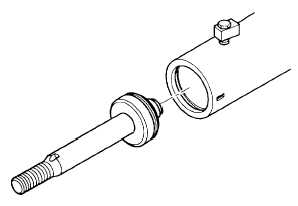

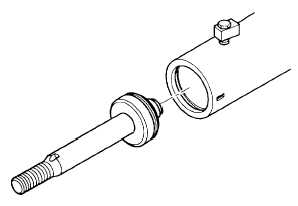

6.

Remove the gland seal, gland packing and

piston rod wiper. Discard old seals.

7.

After cleaning and inspection (see below), install

new gland seal, packing and rod wiper.

Inspection

1.

Carefully clean all parts in an approved solvent

and place on a clean surface.

2.

Check the piston rod for damage. Look for

gouges, scratches, corrosion or evidence of

unusual wear. Minor surface damage may be

repaired by use of fine abrasion cloth or stoning.

Deeper damage will require replacement of

piston rod assembly.

3.

Be sure the threads on rod are undamaged.

4.

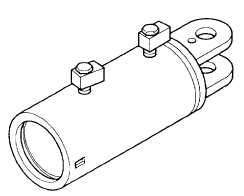

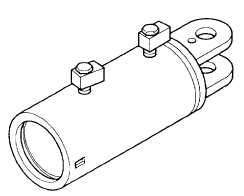

Inspect the tilt cylinder barrel internal bore for

wear, scratches or other damage. Check the

outside for damage. Inspect all welds for cracks.

Deep gouges or pitted surfaces require replacement of

parts.

F-478

|