| |

TM 10-3930-671-24

8.

Stop the upright when the first tilt cylinder bottoms out

against its rod spacer. Use rod shims to fill in the space

between the rod end and spacer on the opposite tilt

cylinder.

NOTE

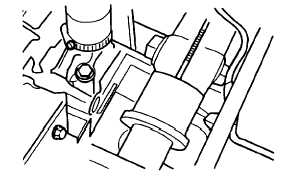

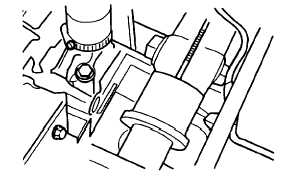

Shown is a standard tilt cylinder with spacer. Uprights

with MFH of more than [3912 mm] 154 in. use spacers to

restrict back tilt.

9.

After the excess space is taken up by the

adjusting shims, retest the full forward and

backward tilt for correct adjustment.

Tilt Cylinder Removal

Refer to tilt cylinder mounting illustration.

NOTE

To perform this service procedure, it is recommended

that you first:

•

Park truck on a level surface.

•

Put the upright in a vertical position and

lower the carriage fully down.

•

Return all controls to neutral and turn key

switch OFF.

•

Apply the parking brake and block the

wheels.

1. Be sure all hydraulic attachments are secured

and upright and carriage are in the fully-lowered

position.

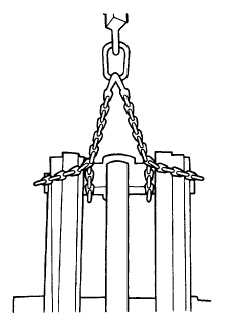

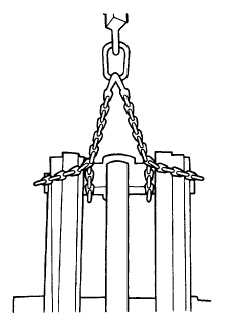

2. If both tilt cylinders are to be removed, the

upright must be supported by use of an

overhead chain hoist of adequate capacity.

Attach a chain or sling to the upright and a hoist before

removing any tilt cylinder or upright attachment parts. Be

sure to secure and support upright from falling before

removing tilt cylinders. Failure to secure upright could

result in injury or death.

F-473

|