| |

TM 10-3930-671-24

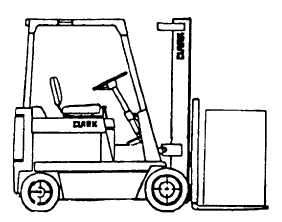

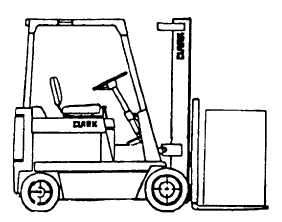

Tilt Cylinder Adjustment

Upright twisting (racking) occurs when tilt cylinder

strokes are unequal due to misadjusted rod ends, and/or

tolerance stackup in parts.

1.

Check condition of the tilt cylinder, rod end,

mounting pins, piston rod, rod wiper, cylinder

gland, etc., for excessive wear or damage. Make

repairs before making twisting adjustment.

Test For Upright Racking

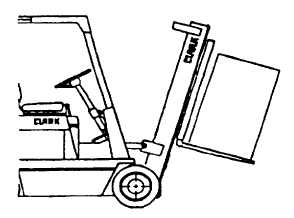

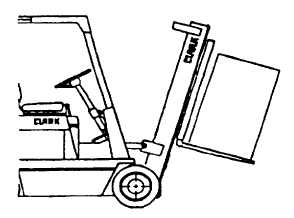

2.

Use a capacity load (see truck nameplate)

centered on the forks. Raise the upright only to

the height that will allow the fork tips to clear the

floor when tilted fully forward.

Be sure to secure the load to the fork carriage to keep it

from falling off when tilted forward or damage to

equipment could result.

3.

Slowly tilt upright fully forward.

4.

Watch both piston rods for equal movement and

upright for twisting. Note if upright "racks" (is

twisted during its movement by unequal stroke of

tilt cylinders).

NOTE

Correct the twisting effect by shortening the cylinder that

is the longest length. Forward twisting must be adjusted

before backward twisting. If forward adjustment is not

needed, continue with Step 7.

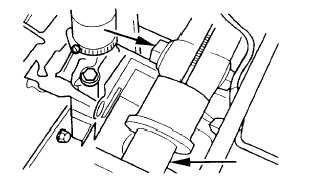

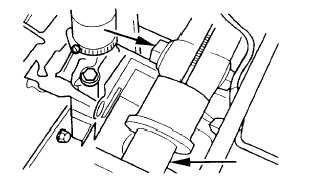

5.

To adjust, loosen rod end clamp bolt on the tilt

cylinder that extends the farthest, and turn piston

rod into rod end to shorten.

NOTE

Use wrench flat on rod end under spacer (if installed).

Move spacer for access.

6.

Continue to turn rod into rod end until tilt cylinder

strokes are equal. Tighten rod end clamp bolt.

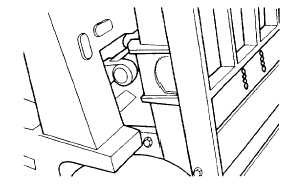

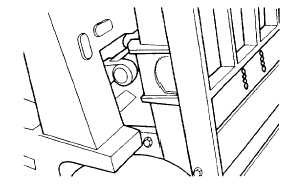

Backward Adjustment

7.

Slowly tilt upright fully backwards while watching

piston rods. They should both bottom out at the

same time. If they don’t, adjust backward tilt as

follows.

F-472

|