| |

TM 10-3930-671-24

NOTE

Use recommended fluid only. Refer

to Group 2.1, Service Specifications,

for fluid specifications.

9.

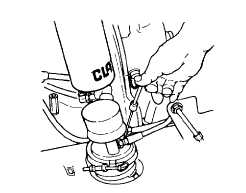

Fill sump tank with new fluid. DO NOT

OVERFILL.

NOTE

Remove or pull dipstick part of the

way out to vent air from tank while

refilling.

10.

Install new sump breather cap.

Check Operation of Hydraulic System

WARNING

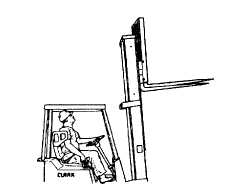

Be sure there is adequate overhead

clearance before raising the upright

or damage to equipment or injury

could result

1.

Start the engine and operate the hydraulic

system. Cycle the hydraulic system several

times. Raise the lift carriage to the highest

position and lower fully down.

WARNING

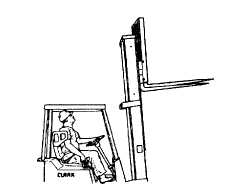

Do not use your hands to check for

hydraulic leakage. Use a piece of

cardboard or paper to search for

leaks. Escaping fluid under pressure

can

penetrate

the

skin

causing

serious injury. Relieve pressure

before disconnecting hydraulic or

other lines. Tighten all connections

before applying pressure. Keep

hands and body away from pin holes

and nozzles which eject fluids under

high pressure. If any fluid is injected

into the skin, it must be surgically

removed within a few hours by a

doctor familiar with this type injury or

gangrene may result.

2.

Check for leaks. Clean up any oil spills.

3.

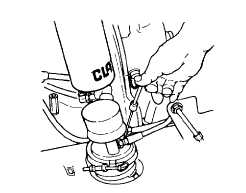

Check hydraulic sump fluid level. Add fluid, as

necessary, to bring the oil level to the correct

FULL level as shown on dipstick. Do not overfill.

4.

Stop the engine. Turn key switch OFF. Close

the engine compartment. Remove blocks from

the wheels, if used.

This completes the procedure for changing the hydraulic

fluid and filter.

F-453

|