| |

TM 10-3930-671-24

12.

(Omit installation of shim pack.) Assemble the

knuckle pin cover, bearing and seal assembly

through lower bore in axle body and onto lower

knuckle pin.

13.

Prior to installation of knuckle pin cover (bearing

cup retainer) capscrews, apply 80-100 Ib-ft

(109136 N-m) load against knuckle pin cover

while rotating steer knuckles back and forth 3 or

4 times thru approximately 900 to seat the

knuckle pin bearings.

NOTE

Knuckle pin cover capscrews may be

installed and partially tightened to

seat the knuckle pin bearings.

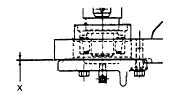

14.

With a thickness gauge, measure the clearance

(dimension X) between the axle body and the

knuckle pin cover.

15.

Select appropriate shims from shim pack that

will add up to a total shim thickness of .005-.009

in. (0.127-0.229 mm) less than dimension X.

16.

Remove knuckle pin cover. Install correct shim

pack as determined above. Reinstall knuckle

pin cover.

17.

Tighten knuckle pin cover capscrews to torque

spec: 15-18 lb-ft (20-25 N•m).

18.

Check the installation of the knuckle to be sure

that it is free to rotate in the bearings without

binding.

19.

Repeat above procedures for opposite end of

axle.

Steering Cylinder Reassembly

Refer to Section 9.13, Steering Cylinder Overhaul (Type

2).

Steering Cylinder and Tie Rod Arm Installation

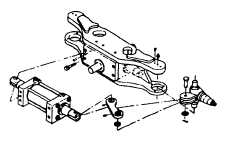

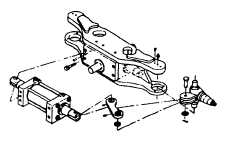

1.

Assemble tie rod arm (link) into each end of the

steering cylinder piston rod. Install pin and

washer. Install new cotter pins and bend tabs to

lock.

2.

Assemble the steering cylinder into axle frame.

Be sure the locator pin is installed in correct

position.

NOTE

If new locator dowel pin is to be

installed, press pin 0.087 in. (0.0-2.2

mm) below outer surface of axle

body.

3.

Install the four steering cylinder mounting bolts.

4.

Tighten steer cylinder mounting bolts to torque

spec: 125-140 lb-ft (170-190 N•m).

5.

Install tie rod arms into steering knuckles. Install

pin and washer. Install new cotter pins and bend

tabs to lock.

6.

Check to be sure all lube fittings are installed.

Fill all lubrication points with correct lubricant.

Refer to Recommended Greasing Procedure.

F-438

|