| |

TM 10-3930-671-24

Assembly

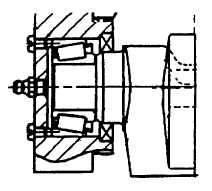

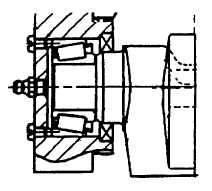

Steering Knuckle & Knuckle Pin Bearings

Reassembly

Recommended Greasing Procedure:

1)

Use Grade No. 1 EP Lithium soap base

multipurpose

grease,

Clark

MS-9B

or

equivalent.

2)

All tapered roller bearings to be packed with

grease before assembly.

3)

Tie rod bearings to be filled using a grease

gun after axle is reassembled.

4)

Apply coating of Grade No. 2EP Lithium

soap base multi-purpose grease, Clark MS-

107C or equivalent, to inside diameter of oil

seals prior to assembly.

1.

Turn axle body upside down or on its side so that

knuckle centerline is horizontal to simplify

installation

of

bearings,

seal

and

steering

knuckle.

2.

Correctly apply grease to (pack) upper knuckle

pin bearing and lubricate knuckle pin seal. See

above for recommended greasing procedure.

3.

Install (press) the upper knuckle bearing cup

fully into steering knuckle upper trunnion bore in

axle body.

4.

Assemble upper bearing cone into bearing cup.

5.

Install (press) new knuckle pin seal into and

against shoulder in seal recess in axle body.

Seal should be flush with outer surface of axle

body. Upper seal lip should be pointing down or

towards knuckle.

6.

Be sure to reinstall the 2 bearing-removal screw

plugs in top of axle body.

7.

Apply grease to (pack) lower knuckle bearing

and

lubricate

oil

seal.

See

above

for

recommended greasing procedure.

8.

Install (press) lower knuckle bearing cup fully

into bore in knuckle pin cover (bearing cup

retainer).

9.

Assemble lower bearing cone into bearing cup.

10.

Install (press) new knuckle pin seal into and

against shoulder in seal recess in knuckle pin

cover. Seal should be flush with open end of

cover. Lower seal lip should be pointing up or

towards knuckle.

11.

Carefully install knuckle through seal and into

upper bearing in steer axle body.

NOTE

Check to be sure RH and LH parts are

installed in correct location.

F-437

|