| |

TM 10-3930-671-24

9.

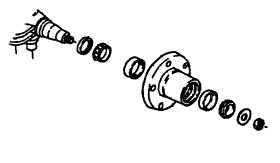

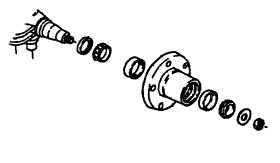

Clean all parts in approved cleaning solvent.

Inspect the bearings and bearing cups for

scratches, cracks, glazing, rust pitting, flat spots

and other wear. Replace damaged parts.

NOTE

Keep serviceable bearing cups and

cones matched together.

Always replace bearing cups and cones as a set.

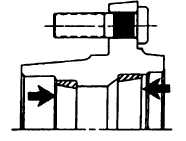

10.

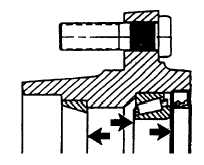

If bearings require replacement, use a standard

puller to remove bearing cups from wheel hub.

11.

Discard grease seal. Replace with new at

assembly.

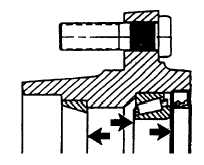

12.

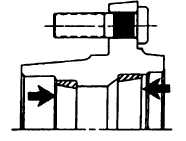

Install new bearing cups by pressing into wheel

hub. Take care to apply an even force to the

bearing cup to prevent cracking during

installation. Be sure that each bearing cup is

fully seated (bottomed out) against shoulder in

hub bore.

F-434

|