| |

TM 10-3930-671-24

10.

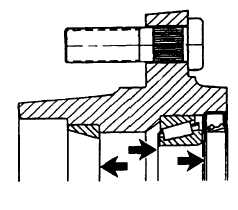

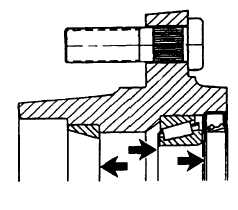

To remove inner bearing and seal, lay wheel (or

hub) down with outer edge up (support hub on

blocking). Remove the inner bearing cone and

grease seal, using a brass drift pin, rod or piece

of pipe to drive the bearing and seal out of the

hub.

11.

Clean and inspect the bearing cups and cones

for wear or other damage. Replace, as

necessary.

Keep serviceable bearing cups and

cones matched together. Always

replace bearing cups and cones as a

set or damage to bearing may result.

12.

Inspect grease seal for wear and damage.

Replace as necessary. It is recommended to

install a new grease seal whenever old one is

removed.

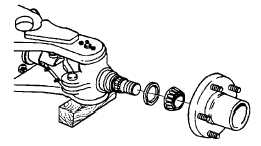

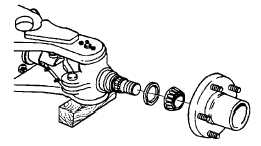

13.

If bearings require replacement, use a standard

puller to remove bearing cups from wheel hub.

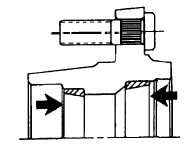

14.

Install new bearing cups by pressing into wheel

hub. Be sure cups are fully seated in bore.

15.

Perform recommended Greasing Procedure:

a)

Use Grade No. 1 Lithium soap base multi-

purpose

grease,

Clark

MS-9B

or

equivalent.

b)

Pack

bearings

with

grease

before

assembly.

c)

Pack cavity in hub between bearings one-

half full with grease at assembly.

d)

Apply coating of Grade No. 2 EP Lithium

soap base multi-purpose grease, Clark MS-

107C or equivalent, to inside diameter of oil

seals prior to assembly.

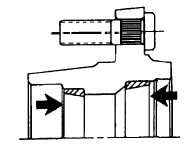

16.

Pack the bearings with grease and install the

inner bearing in the hub.

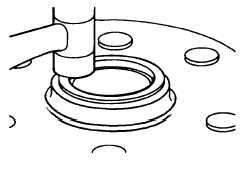

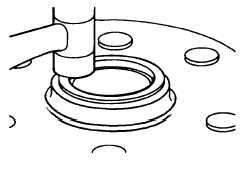

17.

Install new grease seal in wheel hub inner bore.

Apply coating of Grade No. 2 EP Lithium soap

base grease, Clark MS-1 07C or equivalent, to

inside diameter of seal lips prior to assembly,

then install seal in hub bore. Carefully press or

tap grease seal into place with a soft-faced

mallet until seal is seated in bottom of hub bore.

18.

Install wheel hub on spindle. Be careful not to

damage seal lip when moving the hub over the

end of spindle and threads.

19.

Install the outer wheel bearing after it has been

packed with grease.

F-423

|