| |

TM 10-3930-671-24

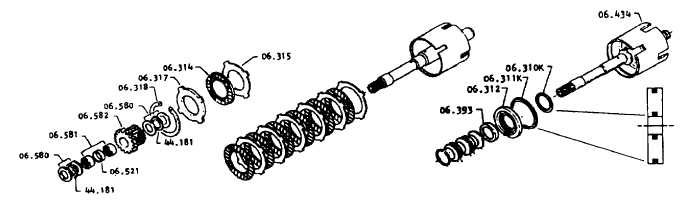

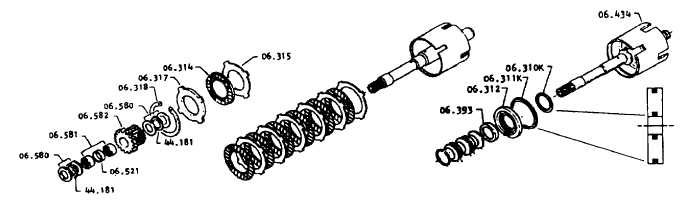

G. Clutch Assembly

Forward clutch reassembly is the same as reverse clutch (shown).

NOTICE - Before reassembly, clean, inspect and

lubricate all parts with a light layer of engine oil.

1.

Install new clutch piston inner and outer oil seal

rings in piston grooves. See figure above.

IMPORTANT - The rings must be sized before piston

installation onto shaft and into the clutch drum:

•

Sizing is best accomplished by rotating the

piston while holding a round object

against the new seal rings.

•

Rotate the piston until the seal rings are

sized flush with the inner and outer

diameters of the piston.

2. Install clutch piston over turbine (clutch) shaft

and into clutch drum.

3. Install clutch piston wear plate (flange towards

piston).

4. Install piston return springs (Belleville washers).

Install first washer with large diameter of bevel

toward wear plate. Alternate five (5) washers.

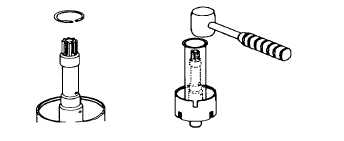

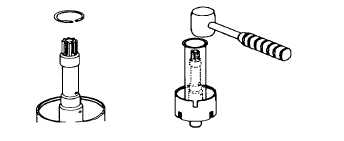

5. Position return spring retainer ring on clutch

shaft. Start ring on shaft with snapring pliers.

6. Install retainer ring using a sleeve with the

proper inner diameter to fit over shaft and

against retainer ring. A sharp blow with a sott

hammer will compress springs and seat retainer

ring. Be sure ring is seated fully in position in

ring groove.

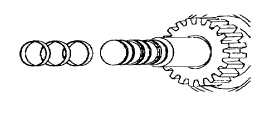

7. Install the first outer (steel) clutch disc against

clutch piston. Next, install first inner (friction)

clutch disc. Alternate outer and inner discs to

install a total of 6 outer steel plates and 6 inner

friction plates.

8. Install clutch disc end plate.

9. Install end plate retainer ring.

10. Check clutch disc clearance. See note below.

NOTE

Both clutch packs (Forward and Reverse) must

be checked for clutch disc clearance:

1)

Stand the clutch assembly on end. The

clutch discs on the bottom will fall to the

end plate.

2)

Measure the distance between the clutch

piston and the first steel disc by inserting a

feeler gauge through the slots in the clutch

drum.

3)

Required clearance is .048-.105 in.

(1.222.66 mm)

4)

If clearance is greater than .105 in. (2.66

mm), add one steel disc under the end

plate.

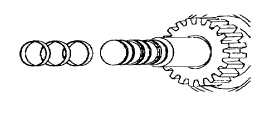

11. Install inner clutch gear thrust bearing set (thrust

bearing between 2 thrust washers).

12. Assemble clutch gear bearing (spacer between

bearings) into clutch gear hub.

13. Install clutch gear into clutch assembly by

aligning the clutch hub teeth with the clutch inner

discs. Be sure the clutch hub is fully in position

in the clutch assembly. Do not force this

operation.

14. Install outer clutch gear thrust bearing set, with

thrust bearing between thrust washers, against

clutch gear.

15. Repeat assembly procedures, Steps 1 through

14, for forward clutch.

16. After forward clutch is assembled, install new oil

distributor seal rings on clutch shaft. Apply

grease to rings to facilitate assembly into oil

distributor.

F-373

|