| |

TM 10-3930-671-24

4.

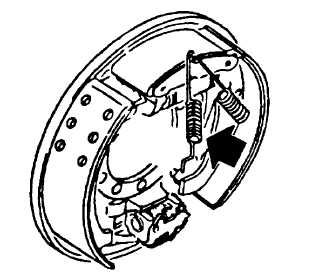

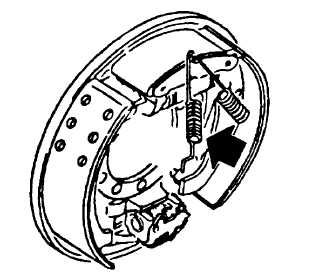

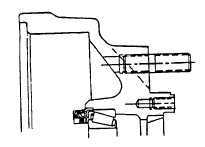

Connect parking brake cable to the notch in the

brake cam.

5.

Assemble the brake shoes and hold-down

springs on backing plate.

6.

Install lower return spring.

7.

Install upper return springs.

NOTICE - For brake adjustment, refer to J. Service

Brake Adjustment procedure.

Wheel Hub Assembly

1.

Install the outer and inner bearing cups.

2.

Position inner tapered bearing in bearing cup.

3.

Apply a very light coating of Loctite #515 to outer

diameter of a new wheel hub oil seal and install

seal in wheel hub.

NOTICE -A special driver, Chicago Rawhide Part No.

448-5, is used to install the wheel hub oil seal.

IMPORTANT - It is mandatory to replace the wheel hub

oil seal whenever the hub is removed from spindle This

oil seal is a type that seals internally, and is lined with

sealing compound on the inner diameter that sticks and

seals to the spindle. Removing the wheel hub from the

spindle breaks that seal. The seal cannot be reused.

4.

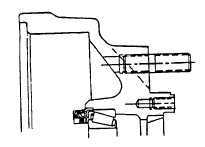

Position wheel hub assembly on the wheel end

spindle. Be careful when sliding oil seal onto

wheel end housing. Support the wheel hub to

avoid seal dragging over spindle.

5.

Install wheel hub outer tapered bearing.

6.

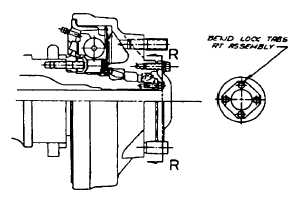

Install wheel bearing shims, retainer plate,

retainer lockplate and capscrews.

7.

Tighten bearing retainer capscrews to torque

spec: 12-16 Ibf.ft. (16-22 N.M.)

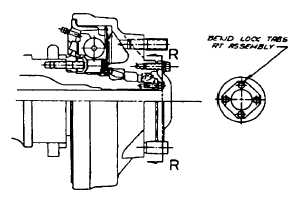

8.

Use a dial indicator to check bearing endplay.

Correct endplay .0005-.0030 in. (0,013-0,076 mm)

Add or subtract shims under bearing retainer plate to

obtain the correct end play.

9.

When endplay is correct, bend the tabs of the

lockplate against the capscrew heads to lock

them.

10.

Apply a film of Loctite #515 to the axle shaft

flange. Spread evenly around the bolt holes.

11.

Apply Loctite #515 to threaded holes in the

wheel hub.

12.

Install axle shaft in wheel end. Rotate shaft to

align axle shaft splines with side gears in

differential.

13.

Install axle shaft mounting screws. Tighten to

torque spec: 80-88 lb-ft. (108-119 N• m).

F-372

|