| |

TM 10-3930-671-24

F.

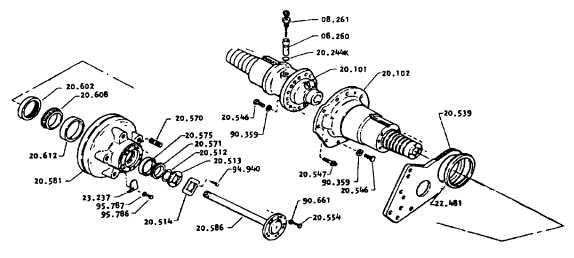

Wheel End Final Assembly

Before final assembly, clean and lubricate all parts

thoroughly.

After the correct ring gear and pinion backlash and tooth

contact is set:

1.

Remove both wheel end housings and apply

a film of Loctite #515 to the flange on

housing. Spread the material evenly on the

flange around the bolt holes.

2.

Position the wheel ends on transmission

case. Be sure differential bearings are aligned

and fitted correctly.

3.

Apply a thread locking compound, e.g.,

Loctite #515 as follows:

a)

On bolts, capscrews and studs (anchor

end), apply compound on the female

threaded component part.

b)

On nuts, apply compound to the male

thread of mating fastener.

c)

Apply compound to coat the full length and

circumference of thread engagement.

d)

Remove excess compound from mating

parts after fastener installation.

4.

Install

the

wheel

end

housings

to

transmission

case.

Install

washers

and

mounting bolts. Tighten bolts to torque spec: 80-

88 Ibft. (108-119 N.M.).

5.

If brakes were removed, install drive axle

mounting support and spacer on each axle

end.

Install brake assemblies

As required

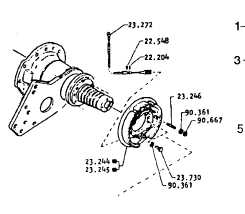

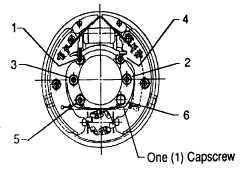

1.

Insert parking brake cable (through the opening

noted at disassembly) in the brake backing plate.

2.

Install backing plate over(s) studs with washers

and nuts. Install one (1) cap screw and washer

per brake, located closest to parking brake cable

connection.

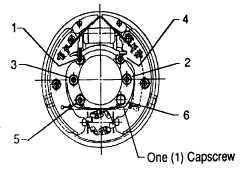

3.

Tighten the fasteners in the sequence shown to

torque spec: 115-129 Ib-ft (156-175 Nom).

F-371

|