| |

TM 10-3930-671-24

E. Trial Wheel End Assembly

For Ring & Pinion Gear

Contact & Backlash Check

(Pinion Gear & Differential Installed)

1.

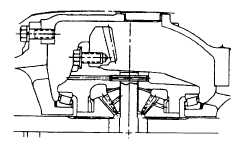

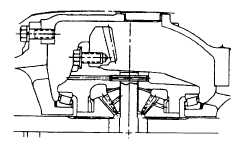

Position the differential assembly in transmission

case.

2.

Assemble the wheel end housings on the

transmission case as marked at disassembly.

Align with differential bearings.

3.

Install the wheel end housing bolts and washers.

Tighten bolts to torque spec; 80-88 lb-ft. (108-

119 N•m).

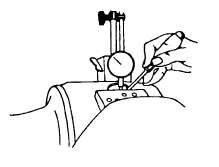

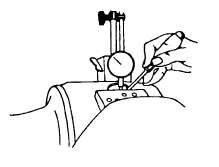

4. Check ring and pinion gear backlash. Open the

inspection cover on the top of the differential

case Set up and position a dial indicatoron a ring

gear tooth to check the ring gear to pinion

backlash. Hold pinion, move ring gear within

backlash free play range several times. Backlash

should be measured at 3 places minimum

around the ring gear (rotate ring gear).

The backlash must be as indicated on the outer diameter

of the ring gear as "BL".

To set the correct backlash, shims behind the tapered

bearings on the wheel end housings are removed from

one side and added to the other. Remove the wheel end

housings, remove bearings and move shims. Repeat

above assembly and checking procedure.

5. Check ring and pinion gear tooth bearing contact

pattern.

• Also refer to Spiral Bevel and Hypoid Tooth Bearing

Contact Chart, Section 7.0.

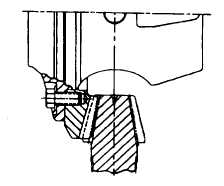

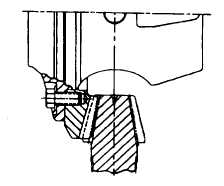

To check the ring gear and pinion for proper tooth

contact pattern (correct position). apply a coating of gear

checking compound. e.g., red lead. to the ring gear teeth

Rotate the ring and pinion gears through a minimum of

one revolution Apply a load (hold by hand) to the gears

as they are turned When the ring gear is turned the

compound is squeezed away by the contact action at the

teeth, leaving bare area that are the exact shape. size

and area of the tooth contact pattern.

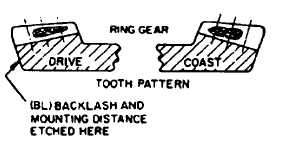

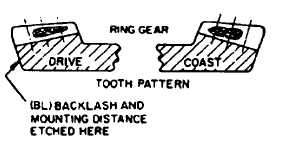

Check the tooth contact area on the drive (convex) side

of the ring gear teeth See figure above for typical correct

tooth contact pattern If the tooth contact is not as shown,

recheck the pinion mounting procedure and also the ring

and pinion backlash reading. Disassemble the parts, add

or remove, or move shims as needed to adjust pin ion or

ring gear position and backlash and recheck.

IMPORTANT- Each time the ring gear or pinion is

moved, the backlash and the bearing preloads must be

checked and reset as needed.

F-370

|