| |

TM 10-3930-671-24

22.

Remove main pump and gasket from aux pump

drive pad on transmission.

23.

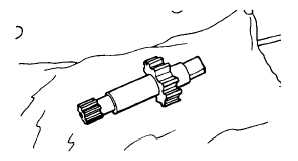

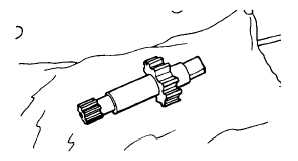

A tool to fit into the aux pump drive sprocket, for

rotating the torque converter and flywheel and

provide access to converter mounting fasteners,

can be made from a discarded pump shaft by

grinding a wrench flat on the shaft.

24.

Fit the rotation tool into the aux pump drive

spline and, using a wrench, slowly move the

converter

and

flywheel

from

one

fastener

position to the next.

NOTE

If a discarded pump shaft is not

available, a flat bar may be ground to

fit into the splines to rotate the

flywheel.

Be careful not to damage the splines

when inserting the bar or equipment

failure may result.

Alternate Procedure: The engine flywheel can be

rotated by using the fan belt or crank pulley.

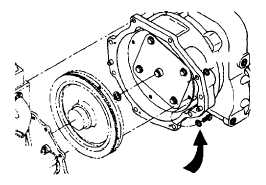

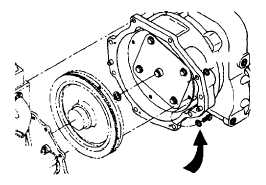

TA 18 Transaxle Converter Fasteners (4)

25.

Remove the fasteners attaching the torque

converter to the flywheel. Use the rotation tool

noted above to rotate the converter and flywheel

to provide access to each fastener by moving

the fastener into a position where it can be

reached through the access opening in the

converter or flywheel housing.

26.

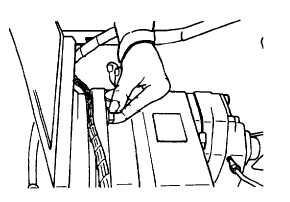

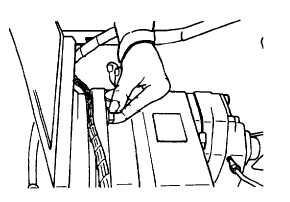

Arrange blocking or other engine support means

under the rear of engine, e.g. at engine rear

plate or flywheel housing, to support engine

when transaxle is removed.

NOTE

If a lift truck is used to support the

transaxle while removing, put the

forks close together and in a position

under the unit to fully support it.

Raise the forks until they touch the

transaxle. If a floor jack is used,

carefully put it in position to safely

support the transaxle.

F-335

|