| |

TM 10-3930-671-24

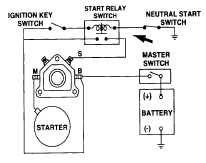

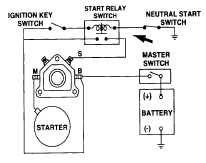

Diagnosis of results: With the engine cranking, a

voltmeter reading of more than 2 volts indicates

excessive resistance in solenoid circuit. For example,

the solenoid is good if the voltage drop is 0.1-1.25 volts.

Voltage readings of 1.25 volts and higher indicate faulty

connections, wiring, switches, or starter relay. Check the

wiring, connections, and switches in this portion of the

circuit.

Starter Removal May Be Necessary

If all other components of the starting system (battery,

starter solenoid, starter relay, switches, and wiring) are in

satisfactory condition, and the engine is known to be

functioning correctly, but starter does not operate or

operate correctly, the starter may have to be removed

from the engine for further testing and repair or

replacement.

Starter Motor Inspection

With the starter removed from the engine, the pinion

should be checked for freedom of operation by turning it

on the screw shaft. The armature should be checked for

freedom of rotation by prying the pinion with a

screwdriver. Tight bearings, a bent armature shaft, or a

loose pole shoe screw will cause the armature to not turn

freely. If the armature does not turn freely, the motor

should be disassembled without further tests. However,

if the armature does rotate freely, the motor should be

given a no-load test before disassembly.

Starter No-Load Test

• Be sure switch is OPEN before

connections or disconnections are

made.

• Do not apply voltage above what is

specified. Excessive voltage may

cause

the

armature

to

throw

windings.

NOTE

It is not necessary to obtain the exact

voltage specified, as an accurate

interpretation

can

be

made

by

recognizing that if the voltage is

slightly higher, the rpm will be

proportionately

higher,

with

the

current

remaining

essentially

unchanged. However, if the exact

voltage is desired, a carbon pile

connected across the battery can be

used to reduce the voltage to the

specified value.

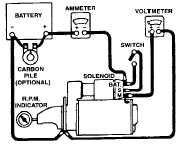

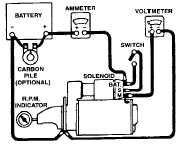

To obtain full performance data on a

starter motor or to determine the

cause of abnormal operation, the

motor should be subjected to a "no-

load" test. This test is performed, as

described below, with the starter

removed from the engine.

The no-load test may point to specific defects which can

be verified with tests when disassembled. Also, the no-

load test can identify open or shorted fields, which are

difficult to check when disassembled. The no-load test

also can be used to indicate normal operation on a

repaired motor before installation.

No-Load Test Procedure

To perform the no-load test, connect the starter motor in

series with a fully-charged 12-volt battery, as described

below. Use an RPM indicator to measure armature

speed. Then read the current draw and the armature

speed and compare these readings with the values listed

in the motor specifications.

F-309

|