| |

TM 10-3930-671-24

ASSEMBLE STATOR TO REAR HOUSING - Place

stator in rear housing, with leads extended toward heat

sink. Assemble diode and stator leads to diode terminal

screws. When properly assembled, each screw will hold

a black lead from a negative diode, a red lead from a

positive diode and a lead from the stator. The terminal

screw nearest to the stator terminal, will also hold the

stator tap lead wire.

Install washers and nuts, secure. Arrange all leads to

prevent accidental contact with surfaces or through bolts.

Align stator slots with through bolt holes.

ASSEMBLE FRONT AND REAR HOUSING - Place

front housing, with rotor assembled, in a vise, drive end

down. Place sealing gasket over top edge of-front

housing. Place rear housing and heat sink assembly

over top end of rotor, align bearing cavity and press

halves together.

Position gasket to align with through bolts. Install bolts

and tighten securely. Spin rotor by hand to insure proper

assembly.

INSTALL BRUSH ASSEMBLY AND COVER - Place

insulator over brush assembly, slide into brush cavity,

position with alignment pins. Secure insulator and brush

assembly to rear housing with screws. Connect brush

lead to cover. Place gasket in recess area, install brush

cover, secure with screws.

INSTALL PULLEY AND FAN - Place pulley soacer over

rotor shaft, install Woodruff key in slot. Place fan and

pulley on shaft and install lockwasher and nut. Secure

nut at 35 to 50 ft. lbs. Spin rotor by hand to insure fan

does not rub housing. This completes the assembly of

the alternator.

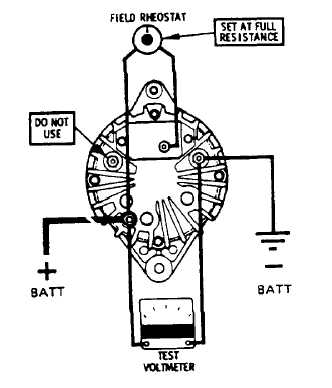

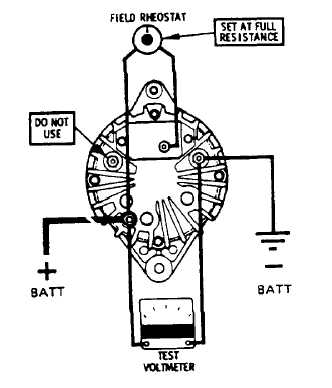

ALTERNATOR OPERATING TEST

(LESS REGULATOR) -

Mount alternator in test fixture capable of providing 3000

to 4000 alternator RPM, in either direction. Connect

circuit leads as shown in (Figure No. 65).

Turn drive motor on, adjust to obtain 3000 to 4000

alternator rotor speed. Reduce resistance of field

rheostat to zero. Alternator should commence to charge

and

reach

rated

output

in

amperes,

within

the

recommended speed range. Obtaining rated output,

alternator is suitable for installation.

Do not operate alternator for more than a few minutes in

this manner, due to the lack of voltage control.

FIGURE NO. 65.

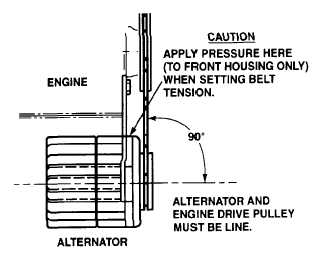

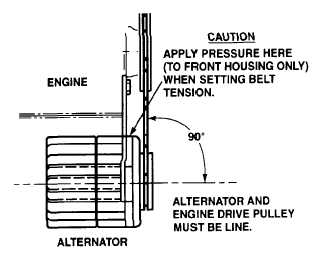

When reinstalling alternator on engine, accurately align

alternator and engine drive pulley (Figure No. 66).

FIGURE NO. 66.

To tighten belt, press against front housing, near

alternator fan. Do not apply pressure to alternator rear

housing.

Set

belt

tension

per

manufacturer’s

recommended specifications and tighten all bolts. If

manufacturer’s specifications are not readily available,

set belt tension tight enough so that the belt on alternator

fan pulley will not slip when attempting to rotate

alternator fan by hand.

F-296

|